I.Introduction

In 2023, the global honey market size was $8.94 billion, with industry forecasts predicting that this number will grow from $9.4 billion in 2024 to $15.59 billion by 2032, with a compound annual growth rate (CAGR) of 6.52%. As health awareness rises, people have gained more awareness of the harm that sugar and artificial sweeteners cause to the body. Consumer intention is gradually shifting toward healthier natural sweeteners, such as honey, and demand for honey and related products, including honey containers for sale, continues to grow.

As a result, more individuals and businesses are investing in the honey industry, and how to package honey for sale has become an issue the industry needs to address. Companies are demanding more honey packaging machinery and honey containers, with increasing requirements for packaging machines and filling machines to meet diverse needs.

Liuzhoume (official website www.liuzhoume.com) has over 20 years of experience as a packaging machine manufacturer. We have summarized our cooperation experience with honey industry clients to bring you this detailed honey packaging guide, helping you choose the right packaging machine and filling machine for your needs.

II. The Importance of Honey Measurement

As a viscous paste, honey’s unit of measurement not only affects the choice of bottles for honey or plastic containers but also determines what kind of liquid packaging machine or piston filling machine you should choose, which deeply impacts your production efficiency.

1. The Debate Between Weight and Volume

When packaging honey, some companies use weight as the unit, while others use volume as the unit. Liuzhoume.com recommends using weight as the packaging unit. If you’re considering expanding your product line, learning how to make honey bottles or researching how to get honey bottles can provide insight into designing practical and appealing packaging.

The reason we believe weight is better is that weight measurements are not affected by changes in honey’s density or temperature, while volume measurements can vary due to thermal expansion and contraction, showing different data in winter and summer. Additionally, consumers subjectively recognize weight more, and if consumers feel that a bottle of honey labeled as 6 ounces (by volume) is light, they may think your product is underfilled, which could damage the brand’s good image.

2. Compliance with Regulations

Firstly, your honey in bottles should not vaguely state “approximately 1 lb.” Does this data refer to the net weight, or does it include the weight of the honey packaging container? Therefore, you should label the “net weight,” so that after consumers purchase a jar of honey, they know exactly how much honey they are getting. Secondly, the net weight data on your honey packaging must be more prominent, so consumers can easily see how much a jar of honey weighs.

III. What Should the Correct Packaging Container Look Like?

Choosing the right container should not only focus on the material but also consider the practicality and aesthetics for your honey packaging.

1. Glass Packaging

Glass is an inert material that does not react with honey, so when made into honey jars, it can effectively protect the honey, ensuring its quality and taste. Glass packaging is quite popular and pairs well with various filling solutions, such as liquid filling machines or piston filler machines, for efficient production. You can choose classic round glass jars or sleek, streamlined honey bottles, both of which are practical and easy to transport and stack.

However, if you want to stand out, consider using uniquely shaped bottles for honey, such as bear-shaped or honeycomb-shaped bottles, which highlight the delicious and natural qualities of honey. Of course, there are also classic vintage Muth jars, paired with cork stoppers and wax seals, which can make your honey packaging more upscale and sophisticated, emphasizing your brand’s tone.

2. Plastic Packaging

Honey in plastic bottles is lightweight and unbreakable, making it more convenient for transportation without the need for the careful handling required for glass jars. Additionally, plastic packaging is more versatile in terms of manufacturing methods. Because plastic is easier to mold, it can be shaped into any design you desire, making it a great option for packaging design. This can make the honey inside the bottle more visually appealing, effectively highlighting your product.

IV. Types of Honey Packaging Machines

The most important machine in the honey packing line is the packaging machine (or filling machine), as its production efficiency determines the overall efficiency of your business. There are many packaging machines available on the market for honey packaging, but how do you choose the right one? Below are several types of packaging and filling machines suitable for honey packaging, with a detailed explanation of their advantages and disadvantages:

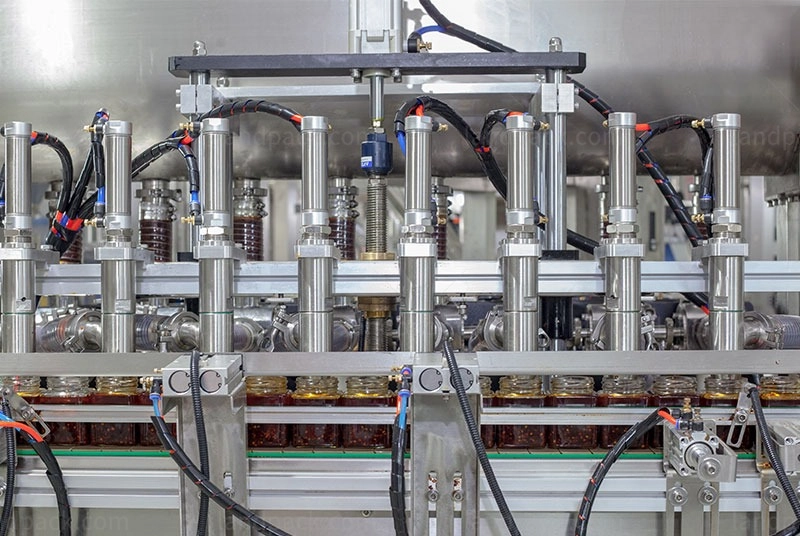

1. Piston Honey Filling Machine

A piston filling machine controls the amount of honey filled by a piston system. Honey flows from a storage tank into the piston chamber, and the piston pushes the honey into the bottle according to the set capacity, completing precise filling.

The advantage of this machine is that it runs stably and fills accurately, making it suitable for honey with different viscosities, especially high-viscosity honey. It can fill honey effectively. The downside is that because it can handle high-viscosity honey, the piston part can easily become clogged, making cleaning more difficult.

2. Gravity Honey Filling Machine

A gravity filling machine uses the force of gravity to fill honey into containers, and the flow speed of honey can be adjusted using valves.

This type of liquid packaging machine has a simple structure. Not only is it easy to operate, but its maintenance costs are also relatively low, making it suitable for small businesses. However, its disadvantage is that it is only suitable for honey with high fluidity. It is not ideal for thicker, more viscous honey.

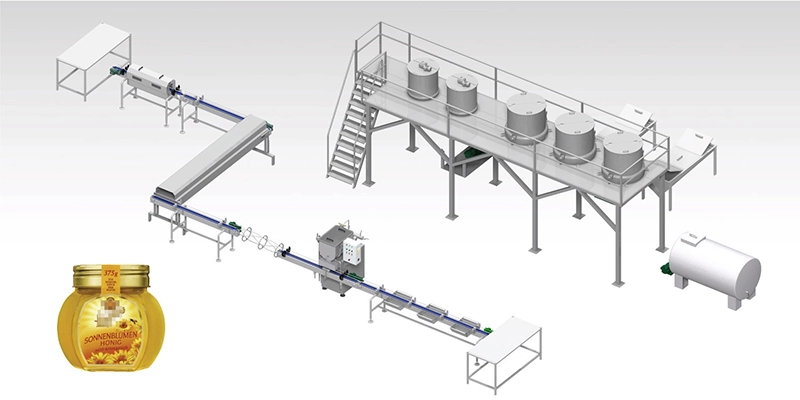

3. Volumetric Honey Filling Machine

A volumetric filling machine uses a fixed volume to determine the amount of honey to be filled, and then uses a pump or piston to transfer the fixed amount of honey into the container.

This type of filling machine is ideal for large-scale honey production. It is highly accurate and stable, and large businesses and factories often prefer it. However, if your production scale is medium or small, or if you do not have a sufficiently large factory to accommodate a volumetric filling machine, it is best not to choose this type.

4. VFFS Liquid Packaging Machine

The VFFS (Vertical Form Fill Seal) packaging machine forms the packaging material vertically, fills it with honey, and seals it. It is widely used for the efficient production of various liquid and granular packaging products, not just honey.

This machine has a high level of automation, which can reduce labor costs. Additionally, its compact footprint makes it suitable for small factories. However, it has a relatively high price. If your budget is limited but you still want a VFFS liquid packaging machine, you will need to carefully select the right packaging machine supplier. Of course, you can also inquire about pricing at liuzhoume.com. As a source factory, we can offer you lower wholesale prices.

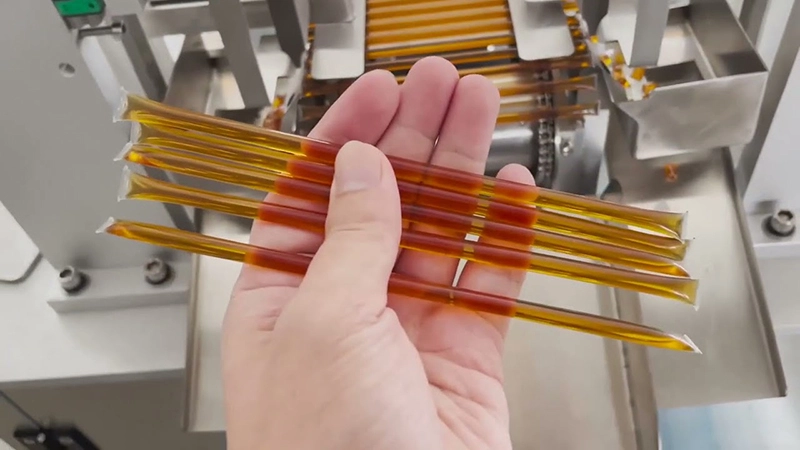

5. Honey Stick Packaging Machine

A stick packaging machine can fill honey into small disposable sticks. The honey filling machine precisely fills honey into small packaging tubes, which are then sealed.

This type of packaging machine is ideal for single-use packaging, making it convenient for consumers to carry and consume. It is more suitable for retail or the foodservice industry for honey packaging. However, because it is a single-use package, the material and equipment costs are relatively high. If you plan to produce large quantities of honey products in larger sizes, it is not recommended.

Liuzhoume.com reminds you not to blindly choose the type of packaging machine. Different types of packaging equipment are suitable for honey producers of different scales and production needs. When selecting, you should consider factors such as production scale, honey type, equipment costs, and market demand.

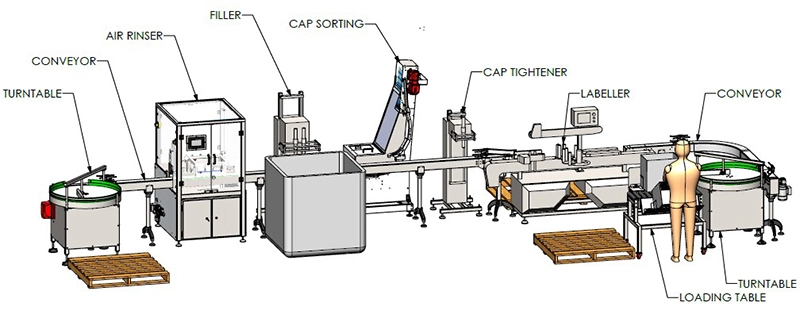

V. Common Packaging Equipment on the Honey Packaging Line

In addition to packaging machines and filling machines, there are several other mechanical devices on the honey packaging line that can improve production efficiency.

1. Sealing Machine

The role of the package sealing machine is to ensure that the honey packaging forms an airtight seal, effectively isolating external air and contaminants, and preserving the honey’s freshness and taste. From the time the honey leaves the production line to when it is purchased and consumed by the customer, changes in external temperature test the sealing quality of the packaging. Therefore, a sealer vacuum packaging machine is essential for maintaining quality.

2. Capping Machine

A capping machine automatically places caps onto bottles for honey or jars. It is one of the key machines for maintaining the airtight seal of honey packaging. If you are looking for a reliable machine to cap your honey in plastic bottles or glass jars, you can consider the products from liuzhoume.com. Our solutions combine stability and professionalism, offering great assistance in improving your production efficiency.

3. Labeling Machine

Labels are crucial for bee honey packaging. While manual labeling is cost-effective, it is not efficient for scaled-up production. Therefore, a labeling machine is an important choice. It can quickly apply labels to honey packaging, displaying relevant product information and allowing consumers to easily access product details.

VI. How to Choose the Right Packaging Machine

1. Assess Your Production Scale

The production scale of large enterprises differs from that of small and medium-sized businesses. If you are a large enterprise or need machines that can scale up production, it is recommended to choose a professional packaging machine manufacturer like liuzhoume.com. They provide tailored solutions, including liquid packaging machines or volumetric filling machines, to create a highly automated packaging line. For small or medium-sized businesses, semi-automatic filling machines are a cost-effective option for maintaining efficiency while reducing initial expenses.

2. Compatibility of the Packaging Machine

Your honey products may require different container sizes and types. For instance, if your product line includes honey in bottles of 500ml and 1000ml, your chosen honey filling machine should handle both. Machines like the piston filling machine are versatile, suitable for various viscosities, and ensure accurate filling. Similarly, a vffs packaging machine can handle flexible packaging requirements while maintaining production efficiency.

3. Scalability of the Packaging Machine

Your business may expand, requiring higher production volumes. A scalable packaging sealing machine or stick packaging machine can adapt to additional equipment or larger-scale production. Ensuring compatibility with industrial packaging machines or customizable configurations will support long-term growth.

VII. Conclusion

Liuzhoume.com reminds you that selecting ideal honey packaging involves combining aesthetics and practicality. Eye-catching designs, such as uniquely shaped honey bottles, paired with efficient machines like the honey straw filling machine, enhance brand trust and consumer appeal. Choosing the right custom packaging machine not only prevents production issues but also optimizes efficiency, ensuring your business flourishes in the competitive honey market.