In a complete production line, packaging equipment is one of the main factors influencing production efficiency, especially for dust-prone powder products. Choosing the right powder packaging machine helps prevent dust leakage while ensuring packaging precision and maintaining a clean production environment. So, how do you choose the right powder packaging machine? Here are several key points you need to know.

I. Definition and Application Range of a Powder Packaging Machine

A powder packaging machine, as the name suggests, is used for packing powder products. Its application range is extensive, commonly used in the food packaging machine, pharmaceutical packaging machine, and industrial packaging machines sectors, such as for seasoning, sugar, salt, fertilizers in agriculture, and cement in construction. Due to its wide application, many companies find it difficult to select the most suitable model among the many types available.

II. Key Points to Consider When Choosing a Powder Packaging Machine

1.Product Suitability

Before purchasing, determine the characteristics of your powder product, which will help identify the suitable type of packaging machine:

A.Flowability of the Powder

You might think that powders, unlike liquids, don’t flow, but they do. Flowability can be categorized as free-flowing and non-free-flowing.

What is a free-flowing powder? A simple explanation is that a powder without stickiness is free-flowing, such as sugar. When pressure is applied to a free-flowing powder, it doesn’t hold its shape or compress. Pouch packaging machines are often suitable for such powders.

On the other hand, non-free-flowing powders are sticky, absorb moisture, and can clump. When compressed, they hold their shape, such as flour or protein powder. To handle these types of powders, filling machines or custom packaging machines with specialized feeding systems may be necessary.

Understanding flowability helps you choose the right filling machine. For example, if you are packaging salt or sugar, a powder filling machine or automatic powder filling machine with gravity-fed filling will suffice. For less flowable powders like flour, a packaging machine manufacturer may recommend a custom packaging machine with a feeding system to ensure efficient packaging.

B. Bulk Density of the Powder

Bulk density refers to the mass-to-volume ratio of a product, including the spaces between particles. For example, sugar (a free-flowing powder) has a low bulk density because it doesn’t compress, making it suitable for automatic powder filling machines. Conversely, flour or rice flour (non-free-flowing) has a high bulk density as it can be compacted, requiring specialized packaging machines for small business or powder filling machines to handle such characteristics effectively.

Knowing bulk density helps assess the volume of packaging needed. For example, a 50g product with low bulk density requires a larger bag compared to a high-density product. This affects costs significantly and may require a suitable pouch packaging machine or automatic packaging machine to handle different sizes efficiently.

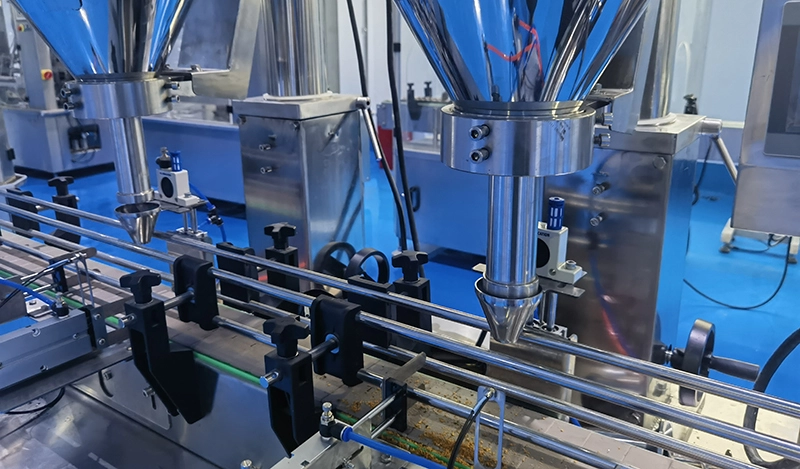

C. Dust Level of the Product

Powders tend to generate dust, which can adhere to the packaging and infiltrate machine parts, potentially causing clogs or malfunction. For high-dust powders, choose machines with sealed designs, such as a sealed air packaging machine or pharmaceutical packaging machine, and an IP-rated dustproof casing to prevent dust leakage and protect critical components, ensuring a clean production environment.

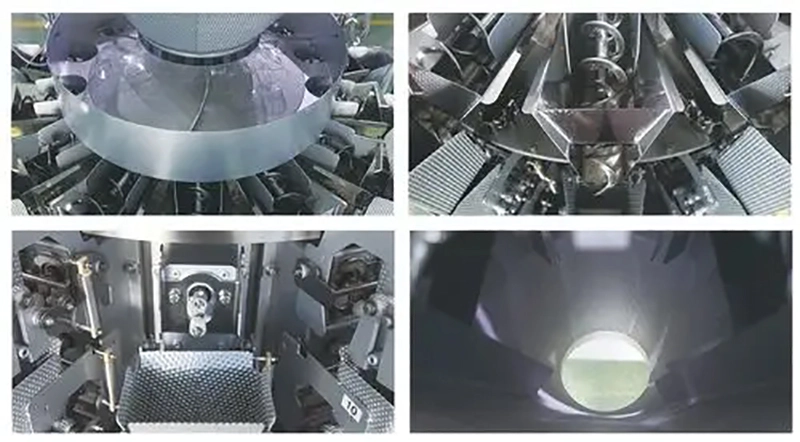

2.Packaging Precision

Precision is crucial, especially for food packaging machines and pharmaceutical packaging machines, where consistency affects customer satisfaction and regulatory compliance. A filling machine for powder with a stable measuring system ensures accuracy, reduces waste, and enhances profitability.

4.Ease of Operation

Complex, multifunctional machines often require specialized training, increasing production challenges and troubleshooting difficulties. A custom packaging machine that balances versatility with user-friendly operation is ideal, reducing labor costs and training time while enhancing efficiency.

5.Level of Automation

Automation is a key factor for modern businesses, affecting labor costs. Large-scale operations benefit significantly from automated packaging machines, while smaller production lines or businesses where labor costs remain manageable might find manual or semi-automatic packaging machines more cost-effective.

6. Material and Hygiene Requirements

The material of the packaging machine impacts product safety. Machines used for food and pharmaceutical packaging must meet high hygiene standards. Stainless steel construction prevents rust and contamination, ensuring product quality and safety.

III. Advantages of Powder Packaging Machines

Efficient Production and Reduced Labor Costs

Powder packaging machines are highly automated, which boosts production efficiency and significantly benefits large-scale production. They also reduce the need for line operators, saving on labor costs.

Prevention of Dust and Contamination

To address dust issues, powder packaging machines are designed with better sealing structures, which is especially critical in the food and pharmaceutical industries.

Higher Packaging Accuracy

Powder packaging machines come equipped with specialized measuring systems to ensure consistent package weight, which is crucial for precise packaging in the pharmaceutical and cosmetics industries.

Adaptability to Various Packaging Forms

These package machines can handle different packaging formats, such as bags, bottles, and jars, offering flexibility for businesses to adjust production and enhance efficiency while reducing costs.

IV.Industries Requiring Powder Packaging Machines

Food Industry

The food and beverage industry has the highest demand for packaging machines. To ensure consistency and efficiency in packaging, powder filling machines are ideal due to their precision, which helps lower costs. Since most food products need long-term storage to maintain shelf life, vacuum packaging machines for food equipped with nitrogen filling features offer excellent results.

Pharmaceuticals and Chemicals

Safety is paramount for these products, requiring high packaging accuracy to maintain consistent dosage, which impacts patient safety. For chemical powders, dust dispersion can lead to exposure to harmful particles, affecting both production efficiency and workplace safety. Powder packaging machines with good sealing prevent dust and ensure safety.

Cosmetics

The cosmetics industry benefits from powder packaging machines not only for their precision and hygiene standards but also for their adaptability. These cosmetic packaging machines can handle different packaging specifications, such as bags, jars, and boxes. Custom machines can also be developed to meet unique packaging requirements.

Construction Materials Industry

Powder products like cement, gypsum, and putty powder are highly moisture-sensitive and require strong sealing capabilities. Powder packaging machines ensure product quality and extend shelf life through excellent sealing.

V.How to Choose a Reliable Packaging Machine Manufacturer

Customization Capabilities

A manufacturer’s ability to customize indicates its expertise. Manufacturers with customization options can provide packaging machines tailored to specific needs, such as those for irregular-shaped bottles.

Cost-Effectiveness

While price isn’t the only factor, a more cost-effective machine with similar features and performance is always preferable.

Experience and Reputation

A packaging machines manufacturer with many years of experience better understands customer needs and can provide professional advice and solutions, even for overlooked aspects.

Recommended: Liuzhou

If you’re searching for a powder packaging machine, we recommend Liuzhou. With over 20 years of experience as a professional manufacturer and supplier, we offer a range of machines, including packaging, filling, labeling, boxing, and palletizing systems. We provide tailored solutions to enhance production efficiency.

As the largest packaging machine supplier in China, we leverage the resources of the world’s biggest industrial economy to maintain high quality while reducing costs, offering competitive pricing for automatic, vertical, and vacuum packaging machines. Visit our website at liuzhoume.com for more information or contact us on WhatsApp: 86-15806004859.

VI. Conclusion

Choosing the right powder packaging machine is vital for boosting production efficiency. When purchasing, consider factors like product flowability, bulk density, packaging accuracy, and automation level. The choice of manufacturer is equally important for ensuring product quality and minimizing maintenance costs.