1. What is a filling machine?

A filling machine is a device specifically designed to fill liquids or viscous products into containers.

What is the purpose of a filler machine? In the food, cosmetics, and chemical industries, these types of Packaging Machines play an irreplaceable role, especially in filling honey, hot sauces, cosmetics, and other thick products. They can significantly enhance production efficiency. Choosing the right filler machine ensures product quality and consistency, which is crucial for the production pace and essential for a company’s competitiveness.

2.Types of Filling Machines

Manual Filling Machine

- A manual filling machine is suitable for small-scale production and is typically operated manually. This type of machine offers a variety of filling ranges, making it ideal for small-batch and diverse production needs. They are usually low-cost, making them suitable for startups or small workshops.

Semi-Automatic Filling Machine

- A semi-automatic filling machine is designed for small to medium-scale production and offers the flexibility of manual or foot pedal operation. This equipment not only increases production efficiency but also allows operators better control over the filling process, reducing fatigue from manual handling.

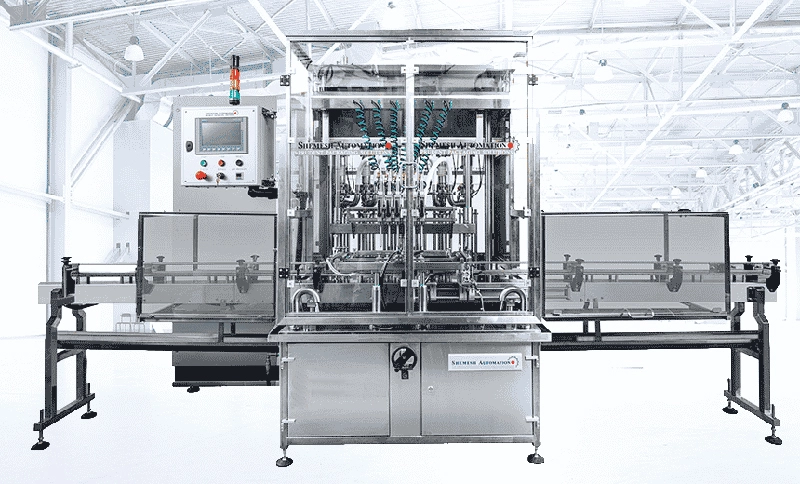

Automated Filling Machine

- An automatic filling machine is the ideal solution for large-scale production, enabling a fully automated filling process. This type of equipment greatly enhances production efficiency and consistency, making it highly suitable for companies requiring high output. Automated filling machines can effectively reduce labor costs while improving safety and hygiene standards in production.

3.Why is Viscosity Important?

When choosing a paste filling machine, it is essential to consider the viscosity of the filling material. Products with different viscosities will affect the filling machine‘s metering system, production speed, and filling accuracy:

Affects the Metering System

- Products with different viscosities require different metering systems. Low-viscosity liquids can be filled by gravity, while high-viscosity products like honey need a pump filling machine or piston filling machine to ensure accurate filling.

Affects Filling Speed

- High-viscosity products have poor fluidity, resulting in longer filling times, which may impact overall production efficiency. Therefore, selecting a suitable filler machine for the viscosity is crucial.

Affects Filling Accuracy

- If high-viscosity materials are not filled properly, they can lead to bubbles or overflow, affecting product quality. The right equipment can improve filling consistency and accuracy.

Material Handling

- Viscosity affects how materials are handled on the production line, as high-viscosity materials may cause blockages. Understanding viscosity helps in selecting the appropriate auxiliary equipment to ensure smooth material flow.

For example, products with higher viscosity, such as peanut butter, may require a specialized pump filling machine to ensure accurate filling. Choosing the wrong filling machine can directly impact production efficiency and product quality, so companies must conduct thorough assessments.

Below are some common material viscosities for reference:

- Syrup: 1,000 – 3,000 cP

- Honey: 2,000 – 10,000 cP

- Ketchup: 30,000 – 150,000 cP

- Peanut Butter: 150,000 – 250,000 cP

- Toothpaste: 50,000 – 100,000 cP

- Shampoo: 3,000 – 8,000 cP

- Lotions and Creams: 10,000 – 100,000 cP

- Mayonnaise: 50,000 – 100,000 cP

- Gel-like Gels (e.g., hair gel): 20,000 – 70,000 cP

4.What Affects the Efficiency of Filling Machines?

Whether it’s a packaging machine or a filling machine, their working efficiency is influenced by various factors that interact to determine the performance of filling machines in actual production. To ensure the efficient operation of filler machines, companies must fully understand these factors and provide relevant information.

Degree of Automation

- The degree of automation directly affects the efficiency of the filling machine. An automatic filling machine can fill continuously and quickly on the production line without manual intervention, making it suitable for large-scale production. In contrast, manual or semi-automatic filling machines are suitable for small-scale production; although they offer operational flexibility, their production efficiency is relatively lower. When selecting a filling machine, companies need to determine the degree of automation based on production scale and expected output to choose the most suitable equipment.

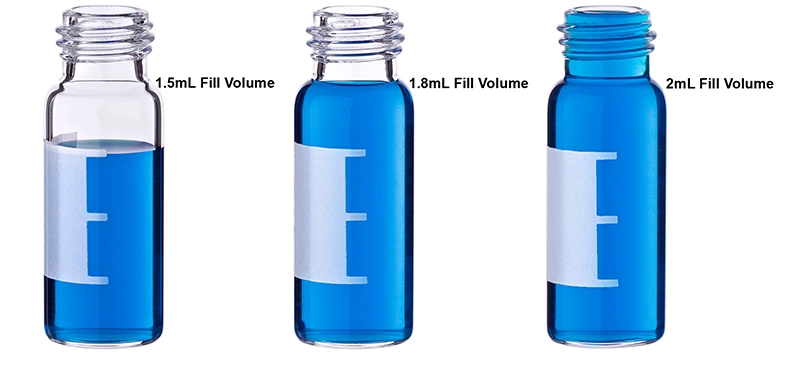

Filling Volume

- Filling volume refers to the quantity of product filled in each cycle. Different products require different filling volumes, impacting production speed and machine configuration. Companies should define the filling volume based on product characteristics and market demand. This not only helps improve filling accuracy but also effectively reduces material waste, ensuring production efficiency.

Bottle Type

- The design and specifications of the bottle type also significantly impact the efficiency of the filling machine. Different bottle types may require different filling devices and adjustment methods. For example, the filling methods for wide-mouth bottles and narrow-mouth bottles differ and may require specialized nozzles or filling heads. Companies should consider the diversity of bottle types when planning production and communicate with the filling machine manufacturer to ensure that the equipment can adapt to different bottle types, avoiding production line downtime.

Specific Material Information and Production Requirements

- To obtain accurate production data, companies need to provide the filling machine manufacturer with specific material information, including the viscosity, fluidity, temperature, and other characteristics of the filling material. This information helps filling machine suppliers recommend suitable filling machines and make necessary adjustments. Additionally, production requirements such as daily output, production time, and changeover frequency should also be considered. Only then can the filling machine manufacturer design the optimal solution based on the company’s actual situation.

By fully understanding and analyzing these influencing factors, companies can optimize production processes, enhance the efficiency of the filler machine, and ensure the stability of product quality and production capacity.

5.Common Filling Mechanisms

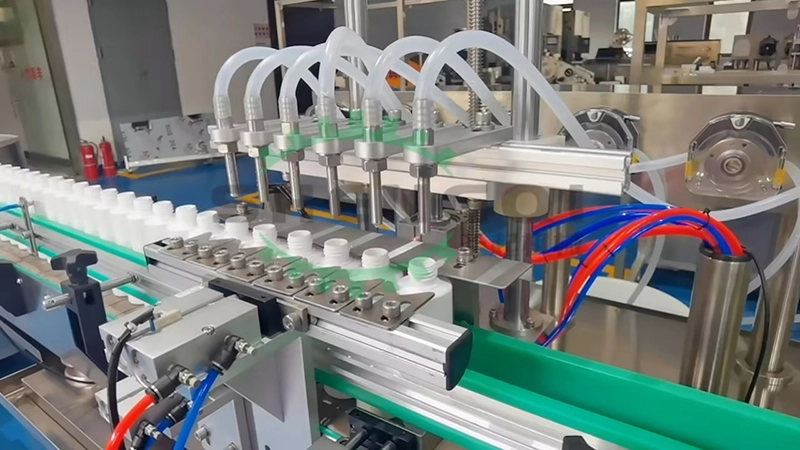

Piston Filling Machine

- The piston filling machine uses a piston for filling, suitable for products of various viscosities. Its simple structure makes it suitable for a variety of production environments and effectively meets the filling needs of different products.

Pump Filling Machine

- The pump filling machine is suitable for high-viscosity products, using different types of pumps (such as gear pumps and rotary lobe pumps) to efficiently handle various viscous materials, like the peristaltic filling machine. This flexibility allows it to be widely used across multiple industries.

6.What Products Are Suitable for Filling Machines?

Common filling products include sauces, jams, creams, and honey. These products are widely used in the food, cosmetics, pharmaceuticals, and chemical industries, such as sauce filling machines and cosmetic filling machines. The choice of industrial filling machines is crucial for product quality and production efficiency. As market demands change, companies should regularly evaluate their product lines to timely adjust their filling equipment.

7.Customization and Integration

Customization Options

Depending on the specific nature of the product, the paste filling machine offers various customization options to meet different production needs.

- Customizable filling heads and nozzles allow the filling machine to accommodate filling materials of various viscosities and characteristics. For example, a paste filling machine designed for high-viscosity products like honey or hot sauce may require specially designed nozzles to ensure smooth filling.

Customizable filling ranges enable a single filling machine to handle different fill volumes, from small amounts (e.g., 50 milliliters) to large capacities (e.g., 5 liters). This allows the same equipment to process various products, further enhancing production efficiency and saving equipment costs.

Customizable heating and stirring mechanisms are crucial for ensuring the uniformity of viscous products. For certain products, heating may be necessary to maintain flowability, or stirring may be needed to prevent ingredient settling, making this feature very important for the filling machine.

By planning these requirements in advance, companies can respond quickly during new product development or market changes, thereby improving overall market competitiveness.

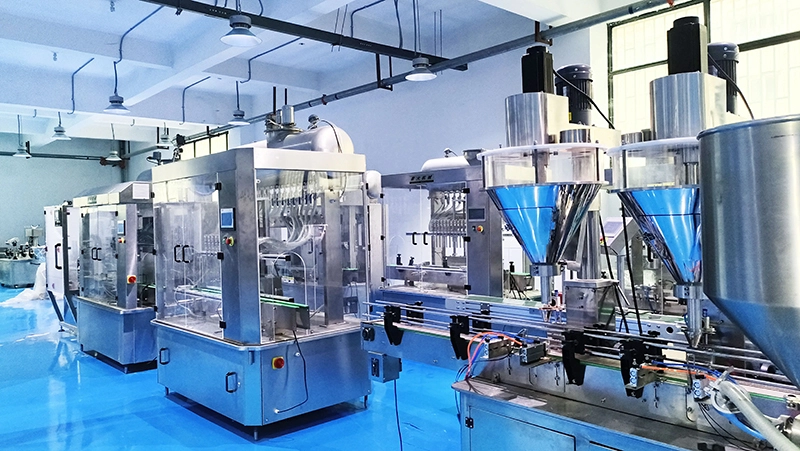

Integration Capabilities

The integration capabilities of the filling machine allow it to connect seamlessly with other packaging equipment (such as sealing machines and labeling machines), forming a complete automated production line. This integration not only provides comprehensive packaging solutions but also significantly enhances production efficiency. For example, when a filling machine is combined with a sealing machine, such as a filling and sealing machine, the entire packaging process becomes more efficient, reducing product dwell time at each stage and shortening the production cycle.

Additionally, an integrated production line can lower labor costs. The automated process reduces dependence on manual operation, enabling companies to handle more products in the same timeframe. This integration not only improves production efficiency but also optimizes resource allocation, resulting in higher profit margins, which is crucial for businesses.

Flexibility

Flexibility is an essential consideration for companies when designing production lines. By customizing filling machines, they can adapt to different types and specifications of containers to meet diverse production needs. Companies can quickly adjust production lines based on market changes and customer feedback, rapidly optimizing production processes. This flexibility greatly enhances a company’s competitiveness.

For instance, when launching new products, companies can quickly adapt to new container designs and specifications by adjusting filling heads and nozzles. This capability allows businesses to respond swiftly to market demands, improving customer satisfaction. Furthermore, flexible production lines enable companies to make adjustments during seasonal demand peaks, maximizing production efficiency.

In summary, customization and integration not only enhance the functionality and adaptability of filling machines but also provide companies with higher production efficiency and market competitiveness. By fully leveraging these advantages, businesses can gain a leading position in a dynamic market.

8.How to Choose a Filling Machine Manufacturer

Consider the Manufacturer's Experience and Expertise

Understand the reputation and success stories of the filling machine manufacturer within the industry to ensure you select a trustworthy partner. High-quality filling machine suppliers can provide more reliable equipment and superior service. Additionally, a filling machine manufacturer with years of experience can offer a more comprehensive range of filling machine models, whether you need a liquid filling machine, powder filling machine, or lotion filling machine, they can provide a one-stop service.

Technical Support and Service

Check the after-sales services, training, and maintenance support offered by the filling machine manufacturer to ensure the stability and performance of the equipment during use. Timely technical support is crucial for the long-term use of the equipment.

Customization Capabilities

Confirm whether the filling machine manufacturer can provide customized solutions based on specific needs to meet the personalized requirements of the business. Customization capabilities directly impact the production flexibility of a company, especially when dealing with different viscosity requirements for paste filling machines; a strong manufacturer can perfectly accommodate your needs.

Quality and Safety Standards

Ensure that the products of the filling machine manufacturer comply with industry standards and hygiene requirements to guarantee the safety of the final product. This is particularly important in the food and cosmetics industries, such as with honey filling machines, sauce filling machines, and other food filling machines, or lip gloss filling machines and lotion filling machines, which are directly related to consumer health.

9.Key Features and Advantages

The distinctive features of a filling machine include drip-proof filling nozzles, food-grade stainless steel construction, adjustable settings, and PLC control systems. These features not only enhance the usability and flexibility of the equipment but also ensure the hygiene and safety of the production process.

If you have non-standard exclusive requirements, you can approach a filling machine manufacturer with customization capabilities (just like us). As a professional filling machine manufacturer, we can provide integrated one-stop solutions, allowing you to have complete peace of mind.

In conclusion, selecting the appropriate paste filling machine and customizing and integrating equipment based on market demand can not only enhance production efficiency but also strengthen a company’s competitiveness in the industry.

Summary

When selecting and customizing a suitable paste filling machine, it is crucial to understand the characteristics of the product, especially the impact of viscosity on the filling process. By clarifying the type, working capacity, customization options, and integration capabilities of the filling machine, businesses can optimize production processes and improve efficiency. Additionally, regularly evaluating and adjusting equipment to adapt to market changes can help companies maintain a leading edge in a competitive environment. Therefore, reasonable planning and choosing the right filling equipment is key to improving production efficiency and ensuring product quality.