I.Introduction: The Necessity of Custom Packaging Solutions

In industries such as food, cosmetics, electronics, and more, the efficiency of the production line directly impacts a company’s profitability. We understand the critical importance of packaging machines within the entire production process. Therefore, we are dedicated to helping our clients enhance production speed and efficiency by designing, manufacturing, and assembling customized product packaging systems.

With over twenty years of industry experience, we have successfully positioned ourselves as one of the top packaging equipment manufacturers. We focus on providing sturdy, reliable, and efficient pack machines to manufacturers in the food, beverage, cosmetics, electronics, and other industries, while offering comprehensive technical support. Our automated packaging machines are designed to enhance the reliability, speed, and efficiency of production lines, ensuring that products are delivered on time and in high quality.

II.Considerations: Designing the Best Packaging Equipment

When customizing packaging machines, clients need to consider several factors, beyond just cost:

Product Characteristics

- Product Type: The packaging equipment must be chosen according to the characteristics of the product, such as liquids, solids, powders, fragile items, or bulk goods. Different types of products have vastly different packaging machine requirements.

- Packaging Form: Consider the packaging form of the product (bottles, pouches, boxes, cans, etc.) to select the appropriate package machines (e.g., filler machines, sealer machines, labeling machines).

- Product Size and Shape: For irregularly sized or uniquely shaped products, customized equipment or specific handling methods may be necessary.

Environmental Factors

Work Environment: Evaluate how the production environment impacts the packaging machines, such as temperature, humidity, and cleanliness. The equipment must be able to handle specific environmental conditions (e.g., high or low temperatures, humid environments, etc.).

Hygiene Requirements: Particularly in the food and cosmetics industries, the packaging equipment must meet hygiene standards and be easy to clean and maintain to prevent cross-contamination or product quality degradation. Hygiene design (e.g., waterproof, corrosion-resistant, stainless steel materials) is essential.

Level of Automation

Automation Level: Evaluate the automation level based on your production process. Fully automated packaging equipment can significantly improve production efficiency, reduce human error, and labor costs, but may have higher initial investment costs. Semi-automated equipment can lower initial investment costs but may require more manual operation.

Integration Capability: Consider whether the equipment can seamlessly integrate with existing production lines, conveyor systems, inventory management systems, etc., to achieve a more efficient overall production flow.

Scalability of Equipment

Future Demand: Consider future production volume increases or product line expansions, and choose packaging machines that offer scalability. Ensure the equipment can quickly adapt to production line additions, new product types, or changes in packaging materials.

Space and Layout

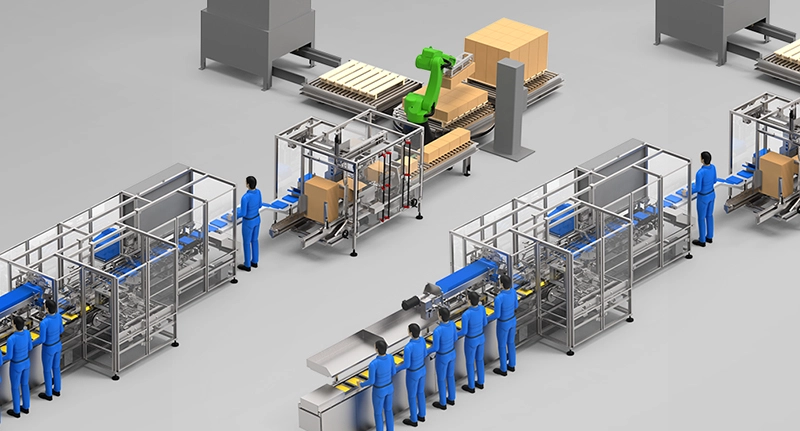

Space Requirements: Evaluate the space occupied by the equipment based on the actual area and layout of the production floor, ensuring that installation won’t interfere with production flow or cause space wastage.

Equipment Layout Optimization: Consider how the layout of the packaging machines aligns with other parts of the production line. Optimizing the production process to minimize material handling and time waste is key.

III.Packaging Equipment for Industry Demands: Finished Products

We provide a variety of packaging machines and supporting facilities to meet the diverse packaging needs of our customers, whether it’s an individual filling machine, vacuum packaging machine, or a complete packaging line, all designed to cater to different packaging requirements:

- Case Erecting and Sealing Machines: These machines select blank cases, form, and seal them. They are suitable for products that require robust packaging, such as beverages and heavy foods.

- Case Packing Machines: These automatically place products into packaging boxes. We offer high-speed or low-speed packaging machines. High-speed packing machinesare designed for high-volume packaging needs, while low-speed machines are ideal for fragile products like glass bottles, ensuring product safety.

- Flexible Pouch Packaging Machines: These are used to accurately fill and seal flexible pouches, especially for dry snacks, pet food, and other products. They also offer sealing and customization capabilities to meet various packaging requirements.

- Filling Machines: These machines are designed to accurately fill liquids, powders, or granular products. They are suitable for a variety of products such as beverages, condiments, food packaging equipment, cosmetics, etc. By precisely controlling the filling volume, they ensure accuracy and consistency in every bottle, enhancing consumer satisfaction.

- Labeling Machines: These machines automatically apply labels, ensuring accurate label placement and compliance with specifications. They are suitable for various bottled and boxed products, especially in fast production lines or when integrated with automatic packaging machines, enhancing packaging efficiency and consistency.

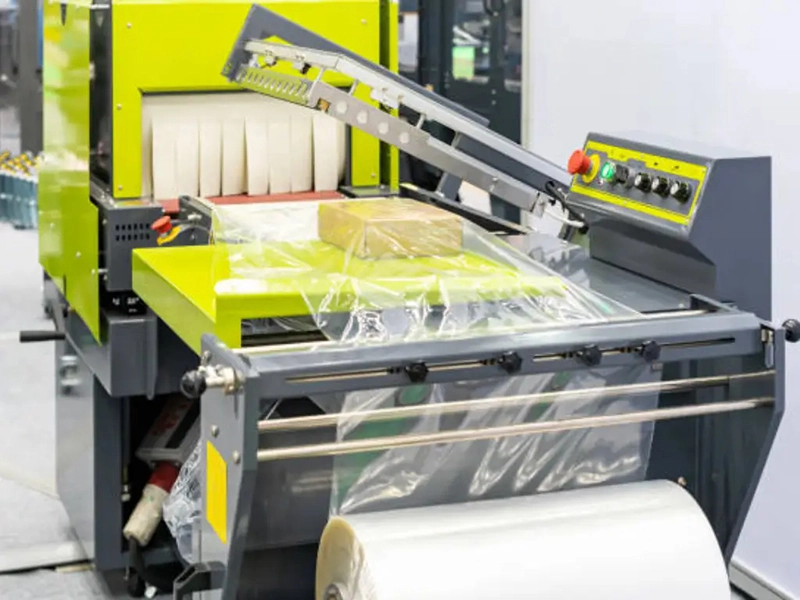

- Shrink wrap packaging machine: These wrap products in heat shrink film, which is suitable for food, beverages, personal care products, and more. Shrink film provides additional protection for products, such as moisture-proof, dust-proof, and easy to store.

- Automatic Case Packing Machines: These machines automatically place products into boxes, with adjustable speeds based on the production line requirements. They are ideal for bulk goods packaging. These machines efficiently increase production speed while ensuring packaging accuracy.

- Strapping Machines: These machines automatically seal and pack finished products, suitable for various packaging methods such as stretch film and box sealing tapes. These machines are widely used in industries like food, cosmetics, liquid packaging machines, electronics, etc., improving the compactness and security of packaging.

IV.Packaging Equipment for Industry Demands: Custom Solutions

We understand that every product and its production process are unique. Therefore, we work closely with our customers to provide customized packaging solutions that meet specific requirements. Whether it’s individual component packaging machines, product assembly, or integration of vacuum packing machines and sealer machines, we have the capability to provide tailored solutions that maximize production efficiency.

Here are some examples of custom projects we have worked on:

Juice Packaging

Project Description: We customized an automatic filling machine for a juice manufacturer, which features high-efficiency filling and capping functions. The equipment utilizes a precisely controlled liquid packaging machine system to ensure accurate juice volumes, reducing waste, and can accommodate bottles of different shapes and sizes. The system also integrates automatic shrink packing machines and labeling machines to ensure product safety and packaging integrity.

Cleaner Packaging

Project Description: We designed an automated packaging machine system for the cleaning products industry, specifically for liquid packaging. This system combines various packaging equipment functions, including liquid filling, cap sealing, labeling, and case packer machines, into a complete workflow. Additionally, the equipment features anti-drip and corrosion-resistant properties, making it suitable for different types of bottle containers (such as plastic bottles, spray bottles). Notably, this equipment can achieve packaging speeds of up to 150 bottles per minute, ensuring high efficiency and precision in large-scale production.

Electronics Packaging

Project Description: We provided an automated packaging system for an electronics manufacturer, specifically for packaging small electronic devices (headphones, chargers, etc.). The system design includes automatic pouch packing machines, product placement, vacuum sealing machines, barcode scanning, and labeling functions. The equipment uses flexible automatic sorting technology to ensure small electronic products are not damaged during packaging. It can also handle different sizes of pouches and boxes, adapting to a wide range of product lines to meet customer needs.

V.Advantages of Our Packaging Equipment: Cost Reduction and Efficiency Improvement

Using our customized packaging machines provides the following advantages:

- Stronger Production Capacity: The equipment is scalable, allowing flexible adjustment of production capacity based on seasonal demand and product volume changes. It ensures production efficiency while meeting production needs, whether with vacuum packing machines or food packaging machine.

- Higher Efficiency: Automated packaging machinescan efficiently and precisely handle repetitive tasks, reducing the workload for employees and allowing them to focus on more challenging tasks. This also helps reduce labor costs effectively, especially with vacuum sealing machines and filler machines.

- Improved Quality Control: The packaging process is optimized for better quality control, preventing packaging defects and label errors. Equipment like automatic shrink packing machinesand sachet packing machines help ensure that packaging is consistently accurate, which helps maintain the reputation of the brand.

- Complete Packaging Series: A full set of automated packaging machines, including strapping machines, vacuum pack machines, and vacuum packaging machines, reduces the risks of manual handling of heavy goods and operating high-temperature machinery, thus improving overall factory safety.

- Reduced Labor Costs: The need for manual operation and supervision is minimized. With a simplified control panel, operators do not need specialized knowledge to operate packing machines or case packer machines, thus lowering labor costs.

VI.Consultation Team: Efficient and Professional Design Solutions

As a strong packaging machine supplier, we have a professional and efficient consulting team that has established long-term partnerships with many clients. Our extensive experience in packaging design solutions allows us to quickly provide you with the best packaging machines tailored to your needs.

We offer a wide range of customized packaging equipment. Whether you require high-quality vacuum packing machines for food packaging, coffee, dairy, meat, poultry, fish, fruits and vegetables, or packaging machines for cosmetics, electronics, and other products, we can perfectly meet your packaging needs.

Additionally, our liquid packaging machines and filler machines are designed for efficient filling of bottles, sauces, and beverages, ensuring the safety of liquid products. If you’re looking for a complete liquid packaging solution, we also provide a range of complementary products, such as bottle labeling, case packing machines, and more. Using state-of-the-art equipment like case packer machines, packing machines, and automated packaging machines, we offer a one-stop solution for your entire packaging line, so you can rest assured.

VII.Contact Us - Start Customizing

Leave the professional tasks to professionals. You are the expert in your product, and we are the experts in packaging equipment.

As a packaging machine manufacturer with over 20 years of experience, our packaging machines are widely used across multiple industries, offering a variety of custom packaging solutions tailored to meet your specific needs. Whether you need a vacuum packaging machine, automatic packing machines, sachet packing machines, or filler machines, we provide the most suitable solution for you. Let us know your requirements, and we will provide the most suitable packaging equipment for you.

Start collaborating with us now. Contact our team to learn more about our industrial packaging machines. Reach us online or via WhatsApp at: +86-15806004859. Additionally, you can visit our website to learn more about our packaging equipment:liuzhoume.com