Automatic Beef Jerky Premade Packing Machine, Pouch Packaging Machine, Food packaging machine, Over 20 Years of Packaging Machine Manufacturing Experience, Source Factory, Super Low Discount Price

Product Overview

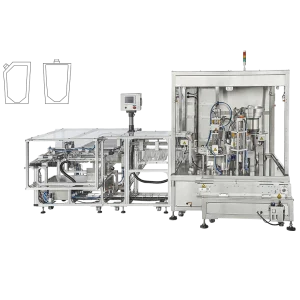

The Automatic Beef Jerky Premade Packing Machine is a high-efficiency, multifunctional solution designed for the precise and reliable packaging of beef jerky and similar products. The machine handles the entire process from feeding, measuring, filling, and bag-making to sealing and outputting the finished product. It is equipped with advanced features such as a high-precision servo film conveying system, digital temperature control, photoelectric tracking, and a user-friendly touch screen interface that supports multiple languages.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Machine Type: Fully Automatic Beef Jerky Preformed Pouch Packaging Machine (pouch packaging machine)

Bag Type: Preformed Bags (ziplock bags, stand-up pouches, custom bags)

Bag Size:

- Length: 160-330 mm

- Width: 110-200 mm

Packaging Speed: 10-50 bags per minute (up to 80 bags/min under optimal conditions)

Packaging Range: 10-2000 grams

Power Supply: 220V/380V, 50Hz/60Hz, 6.75KW

Machine Dimensions: 6000 x 3000 x 4000 mm

Main Features

- Automatic Bag Detection: This packaging machine can automatically detect whether the bag is properly opened. If not, it stops the filling and sealing process to prevent material waste.

- Adjustable Operating Speed: The food packaging machine is equipped with a variable frequency drive (VFD) to easily adjust machine speed.

- Siemens PLC Control: The control system uses a Siemens PLC with an HMI touchscreen, making it intuitive and easy to operate.

- Pressure Monitoring: The package machine is equipped with an alarm system to detect abnormal pressure, halting operation to ensure safety.

- Multi-functional Filling Options: Can be used as a sauce packaging machine, spice packaging machine, or meat packaging machine, capable of filling both solid and liquid products, including sauces, seasonings, and jerky-type mixtures.

- Wide Bag Size Compatibility: The clamp width is adjustable, accommodating bags from 110 mm to 200 mm in width.

- Hygienic Design: All parts of the packaging machine in contact with the product and bag are made of stainless steel or food-grade materials to ensure food safety—ideal as a food packaging machine you can trust.

- Low Maintenance: Advanced oil-free bearings reduce maintenance and prevent contamination.

Applications

This versatile packaging machine is suitable for packaging a wide range of products, including:

- Food: Beef jerky, dried meats, nuts, dried fruits, puffed snacks, candy, and pet food.

- Powder Products: Seasoning powders, protein powder, MSG, and cereals.

- Liquid and Semi-liquid Products: Sauces, syrups, and hand sanitizers, also serving as a liquid packaging machine.

- Non-food Products: Hardware parts, small components, and medical supplies.

It is compatible with various packaging materials such as PE, aluminized PE, PET/PE, PP, and other heat-sealable films.

Enhanced Functions to Improve Packaging

- Extended Shelf Life:

- Gas Flushing Option: Integrates inflatable packaging machine functions, injecting nitrogen into the bag after filling to expel oxygen, significantly extending shelf life and preventing oxidation.

- Oxygen Absorber Integration: The packaging machine can include an optional station to insert oxygen scavengers into the bag, further enhancing freshness.

- Custom Filling Solutions:

- Fill large chunks of jerky using a cup filler, use multi-head scales for mixed jerky, or configure for various shapes and sizes of dehydrated meat products.

- Product Settling Station:

- A shaking or tapping mechanism ensures that products settle evenly in the bag, ensuring a consistent and uniform appearance.

- Sanitary Cleaning:

- Designed for easy cleaning and capable of withstanding high-pressure water jets and disinfectant washes, ensuring compliance with hygiene standards.

Workflow

- Bag Feeding: The packaging machine picks up and positions preformed bags.

- Bag Opening: Uses air suction to open the bag.

- Filling: Accurately weighs and fills the product into the bag.

- Gas Flushing (optional): Nitrogen is injected to preserve freshness.

- Sealing: The bag is heat-sealed for a secure closure.

- Coding: Prints the date or batch number on the bag (optional).

- Discharge: Finished, sealed products are ejected from the machine.

Why Choose This Beef Jerky Packaging Machine?

- Increased Efficiency: Automates and simplifies the entire packaging process, reducing labor costs and increasing output.

- Versatility: Suitable for various products and packaging types, adaptable to different production needs.

- High-Quality Seals: Ensures secure, airtight seals that maintain product quality and extend shelf life.

- Safety and Reliability: Advanced monitoring systems and a robust design ensure safe, consistent, and reliable operation.

Contact Us

Get in touch with us today to learn how this fully automatic beef jerky packaging machine can optimize your packaging line and improve the quality of your packaging process!