Automatic Premade Bag Beef Jerky Packing Machine, Pouch packaging machine, Food packaging machine, China’s Largest Packaging Machine Supplier, Factory Direct Wholesale

Product Overview

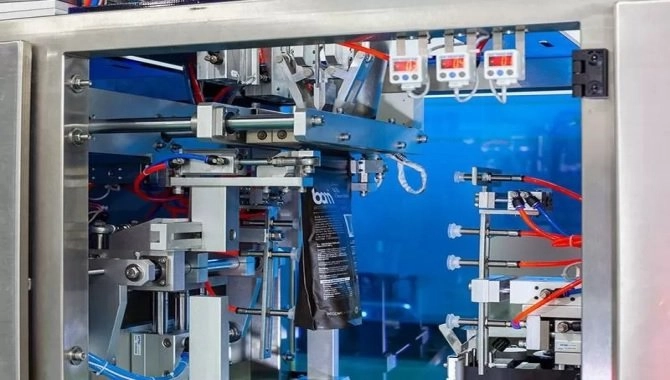

This automatic premade bag packing machine is designed specifically for efficiently packaging beef jerky. It performs a complete series of actions including bag conveying, weighing, filling, and sealing. Equipped with a PLC control system and user-friendly touch screen interface, the machine offers adjustable speed and high precision. It features automatic detection for errors like “no bag,” “bag not opened,” or “seal error,” reducing waste and enhancing efficiency.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Machine Type: Fully Automatic Preformed Pouch Beef Jerky Packaging Machine (a pouch packaging machine)

Bag Type: Corner Seal Bags, Stand-Up Pouches, Ziplock Bags

Bag Material: Composite Preformed Bags (PET/PE)

Packaging Speed: 30-60 bags per minute

Bag Size:

- Width: 20-110 mm

- Length: 40-160 mm

Power Supply: 220V, 50Hz, 1.2KW

Machine Dimensions: 800 x 800 x 2000 mm

Weight: 260 kg

Main Features

- PLC Control with Touch Screen: Easy operation with real-time monitoring of the packaging process.

- Automatic Error Detection: If a bag is missing or incorrectly opened, the packaging machine will stop filling and sealing to prevent product and material waste.

- Adjustable Bag Width: The motor easily adjusts the width to accommodate different bag sizes.

- Safety Features: The packaging machine automatically stops when air pressure is low or the heater disconnects. It also includes a glass safety door; opening it will stop the packaging machine to protect the operator.

- Low Material Loss: Uses high-quality preformed bags with excellent sealing, minimizing material waste, making it an ideal pouch packaging machine.

- Multi-functional Bag Compatibility: Suitable for stand-up pouches, ziplock bags, corner-seal bags, and more.

Applications

This versatile packaging machine is perfect for packaging various products, such as:

- Can be used as a food packaging machine: Beef jerky, dried fruits, nuts, snacks, puffed foods, candy, and more.

- Can be used as a powder packaging machine: Milk powder, protein powder, flour, spices, and food additives.

- Can be used as a liquid packaging machine: Beverages, sauces, and seasonings.

- Non-food products: Pharmaceuticals, hardware items, chemicals, pesticides, and cosmetics.

This packaging machine is compatible with multi-layer composite films, single-layer PE, PP materials, and more, making it suitable for various industries, including food, cosmetics, pharmaceuticals, chemicals, and daily necessities.

Workflow

- Bag Storage: The packaging machine stores and supplies preformed bags.

- Bag Pickup: The robotic arm picks up and positions the bag.

- Coding: Optional coding device prints production details on the bag.

- Bag Opening: The packaging machine uses an air suction device to open the bag.

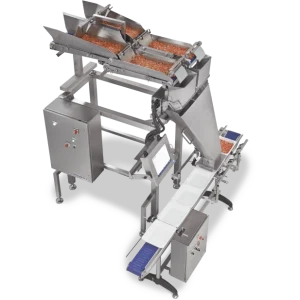

- Filling: The product is weighed and filled into the opened bag.

- Heat Sealing: The bag is securely sealed using heat.

- Product Discharge: The finished sealed bags are ejected from the machine.

Main Components

- Indicator Tower: Displays the machine status.

- HMI (Human-Machine Interface): User-friendly touchscreen control panel.

- Electrical Cabinet: Houses the control electronics.

- Bag Pickup Cylinder: Mechanism to pick up and position the bags.

- Bag Magazine: Stores preformed bags.

- Weighing Fill Hopper: Accurately weighs the product before filling.

- Automatic Zipper Opener: Opens the zippered bags.

- Bag Stabilization Station: Keeps the bag stable during the filling and sealing process.

- Bag Opening Cylinder: Ensures the bag is correctly opened.

- Removable SUS Frame: Stainless steel frame, easy to clean and maintain.

Contact Us

For inquiries or more information, please contact us today to learn how this beef jerky packaging machine can improve the efficiency of your packaging line!