Custom-designed High-hardness Material CNC Vertical Lathe, High-rigidity CNC Vertical Lathe

| ITEM | VALUE |

| Max. length of workpiece (mm) | 470 |

| Max. weight of workpiece(kg) | 6000 |

| No. of spindles | Single |

| Travel (x axis)(mm) | 600 |

| Travel (z axis)(mm) | 600 |

| Positioning accuracy (mm) | ±0.06 |

| Repeatability (x/y/z) (mm) | ±0.003 |

| Place of origin | China |

| Type | VERTICAL |

| Number of axes | 2 |

| Dimension(l*w*h) | 2100*2500*2750mm |

| Tool post stations | 8 |

| Weight | 5500kg |

| Key selling points | High-Accuracy |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

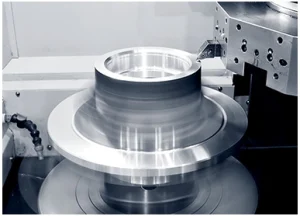

CNC vertical lathes have a wide range of applications, including aerospace, medical equipment, energy, transportation, automobile manufacturing, mold making, heavy machinery manufacturing, and new energy, among many other industries and fields. They can process gearboxes, clutch housings, engine cylinders, crankshafts, gearboxes, transmission gears, disc-shaped parts, pulleys, and other components.

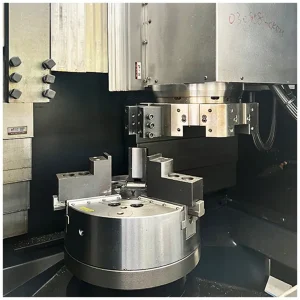

Servo Turret: CNC vertical lathes can be equipped with vertical 4/6-position and horizontal 8/10/12-position tool holders. The internal structure of the tool holder adopts a cam design.

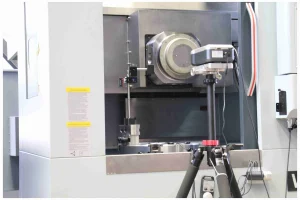

CNC System: A CNC system can be equipped with FANUC, SIEMENS, HNC and other CNC systems to perform precise motion control and process adjustment, thereby improving production efficiency.

Spindle: The CNC vertical lathe adopts a high-speed, high-precision, and high-rigidity unit assembly structure. The spindle bearings use NN series bearings to ensure the rigidity and strength of the spindle unit.

Linear guide structure: It adopts a high-rigidity structure, combined with precision linear guides, and through finite element calculation and optimization design, the size of the CNC vertical lathe is reduced and the rigidity is improved.

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian