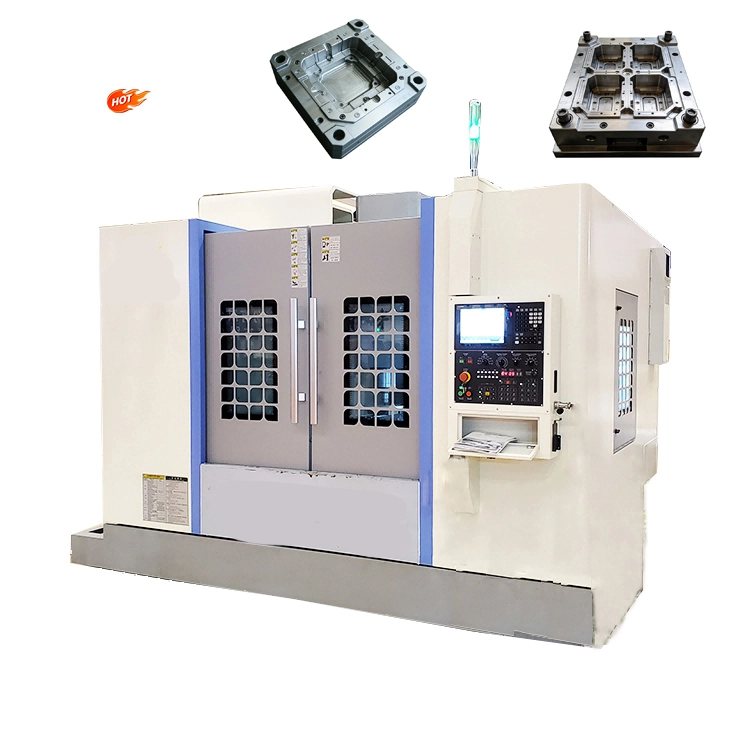

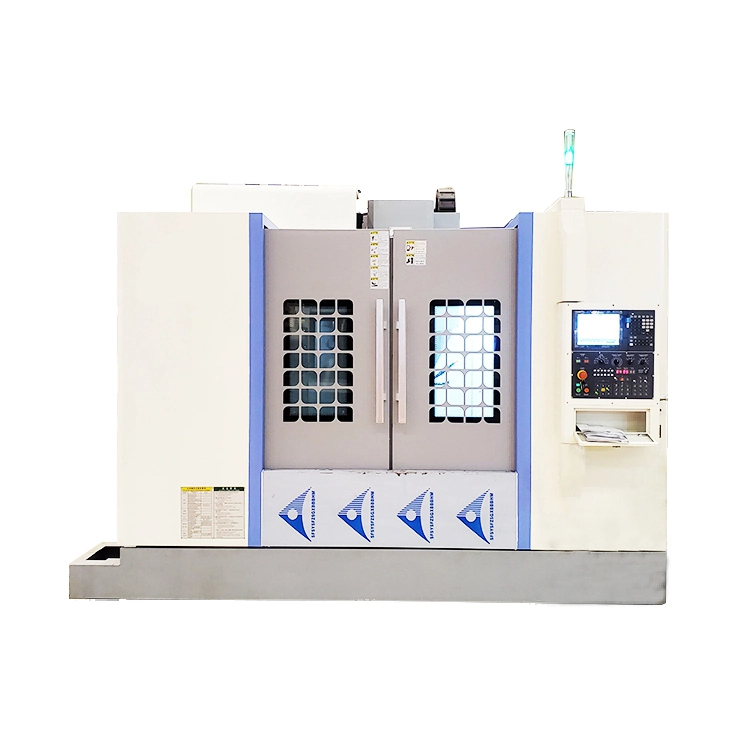

Custom-designed Mold Cavity Machining Center, High-rigidity Three-axis Precision Milling Vertical Machining Center

| ITEM | VALUE |

| Table travel (x) (mm) | 1100 |

| Table travel (y) (mm) | 600 |

| No. of spindles | Single |

| Weight (t) | 7 |

| Table travel (z) (mm) | 600 |

| Repeatability (x/y/z) (mm) | ±0.004 |

| Max. table load(kg) | 1500 |

| Min. time of tool change(s) | 2 |

| Table size | 1500 |

| Place of origin | China |

| Type | Gantry |

| Positioning accuracy | ±0.005 |

| Tool magazine capacity | 24 |

| Key selling points | High-Accuracy |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

Application areas: Machining centers have a wide range of applications, including aerospace, medical devices, energy, transportation, automobile manufacturing, mold manufacturing, heavy machinery manufacturing, new energy, and many other industries and fields. They can process parts such as gearboxes, clutch housings, engine cylinders, crankshafts, transmission gears, drive gears, discs, and pulleys.

Key Features

● Innovative Bed Structure Design: Utilizes a triangular force structure, providing high rigidity and impact resistance to ensure consistently high precision and extended lifespan for machine tools.

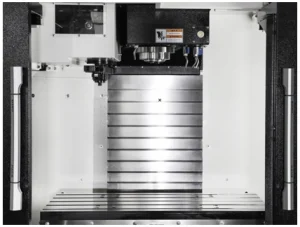

● Worktable: Ultrasonic hardened and precision ground. It performs machining simultaneously with the spindle.

● Chuck: It can quickly clamp products and rotate simultaneously with the spindle for machining.

● Linear Guides: Employs Taiwan Hiwin linear guides, offering high precision, high load capacity, strong stability, and long service life, suitable for high-precision machining requirements.

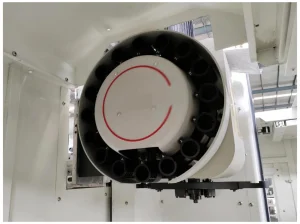

● Tool Magazine: A disc-type tool magazine allows for quiet, rapid, and accurate tool changes.

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

CNC Machining Center

Custom-designed All-aluminum Machining Center with High-precision Milling Machine

-

CNC Machining Center

Custom-designed Heavy-duty CNC Vertical Machining Center CNC Milling Machine