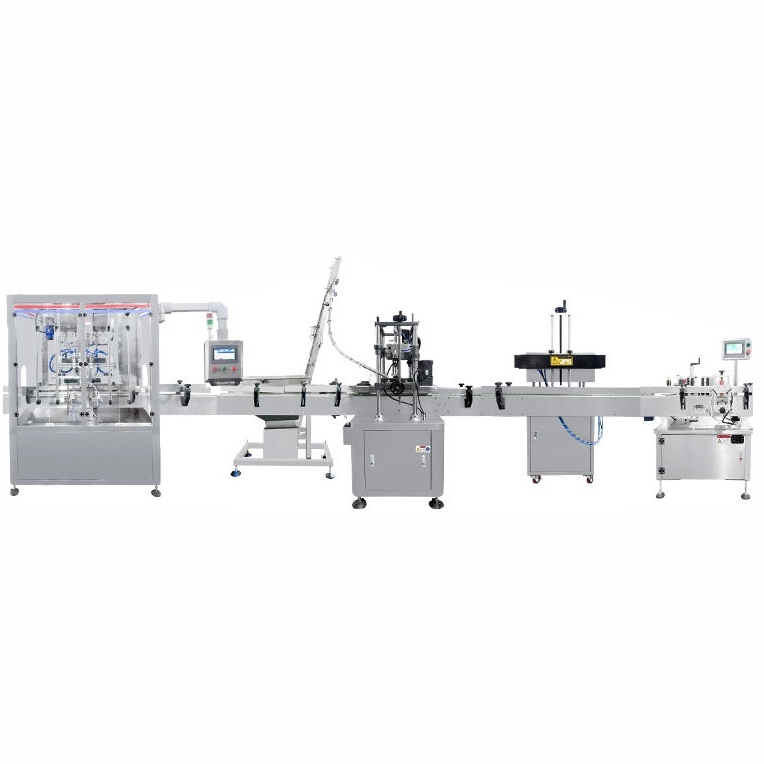

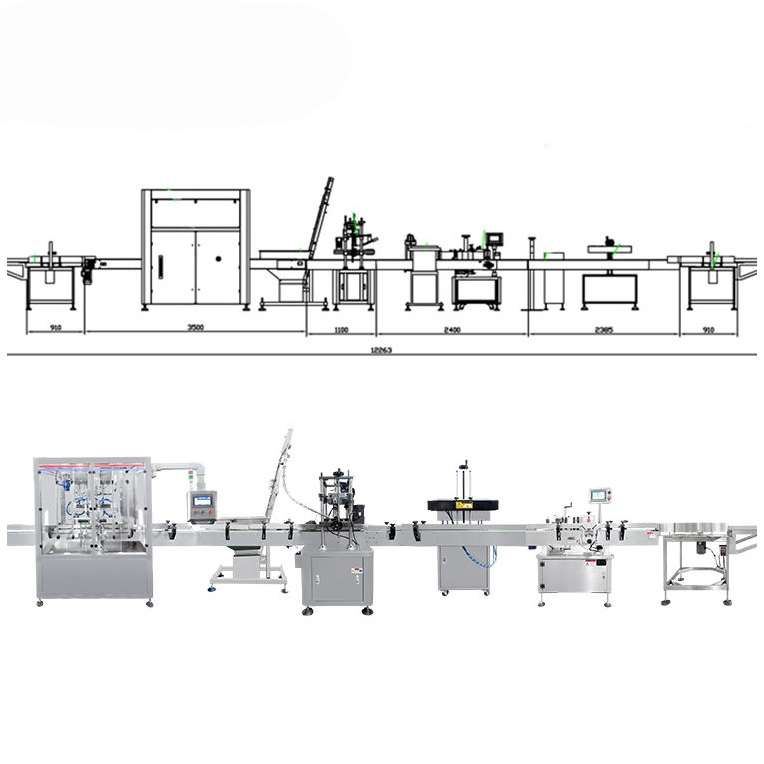

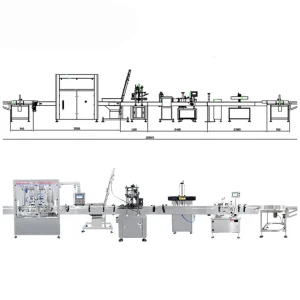

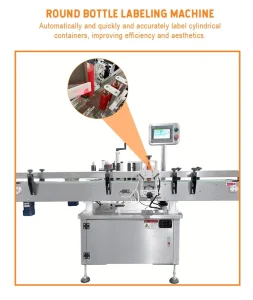

Customized Ink Packaging Machine, Multi-functional Packaging Line, Bottle Labeling Machine, Filling and Capping Machine

| ITEM | VALUE |

| Function | FILLING |

| Packaging type | bottles |

| Voltage | 220 V, 380 V |

| Filling Material | Liquid |

| Weight (KG) | 1200 |

| Automatic grade | Automatic |

| Packaging material | Plastic, Glass |

| Application | Food, Beverage, Commodity, Chemical |

| Place of origin | China |

| Brand name | Liuzhoume |

| Driven type | Electric |

| After-sales Service Provided | Online support, Video technical support |

| Video outgoing-inspection | Provided |

| Customized | Customization supported |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

1. End-to-End Automation and Turnkey Solutions

→ Seamlessly integrate filling, capping, labeling, and coding into a single, continuous operation. This creates a “hands-off” production line from empty bottle feeding to finished product retail-ready output.

2. Maximize Productivity and Output

→ Enable high-speed, simultaneous processing (e.g., hundreds of bottles per minute). Eliminate bottlenecks caused by separate, independent machines, significantly increasing overall throughput.

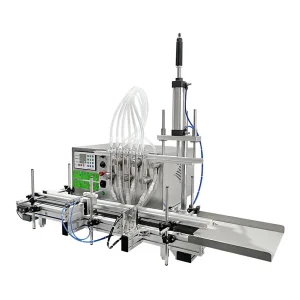

3. Unparalleled Precision and Consistency

→ High-precision filling systems (e.g., servo pistons, volumetric) ensure minimum product give with ±0.5% or better filling accuracy.

→ Precise torque control on caps ensures consistent and secure closure every time.

→ Vision systems and label registration ensure perfect, wrinkle-free label placement.

4. Exceptional Flexibility and Rapid Changeover

→ Handles a wide variety of bottle shapes, sizes, and materials (glass, polyester, PE).

→ Quick-change tools and recipe-driven controls allow for rapid switching between different products and formats in minutes.

5. Significant Savings in Labor and Operating Costs

→ One automated production line replaces the 5-10 manual operators typically required for a single task. This significantly reduces long-term labor costs and management complexity.

6. Enhanced Traceability and Compliance

→ Integrated coding systems (e.g., inkjet, laser) print clear, permanent batch codes, expiration dates, and barcodes on each bottle or label. This is crucial for regulatory compliance (FDA, EU) and supply chain tracking.

7. Superior Hygiene and Safety Standards

→ Constructed with food-grade, easy-to-clean materials (e.g., 304 or 316L stainless steel contact surfaces). The sealing mechanism meets GMP and HACCP requirements for the food, pharmaceutical, and cosmetic industries.

8. Reduced Product Waste and Material Loss

→ “No Bottle, No Fill” and “No Cap, No Fill” sensors prevent waste. Anti-drip nozzles and precise filling minimize product loss and maximize your raw material yield.

9. Robust Reliability and Low Maintenance

→ Designed for heavy-duty components, operating continuously 24/7 in harsh environments. Simplified mechanical and modular design ensures high uptime and direct maintenance.

10. Data-Driven Insights and Control

→ Modern PLCs with intuitive HMIs (Human-Machine Interfaces) enable centralized monitoring, production data tracking, and predictive maintenance alerts for smart factory integration.

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

Liquid Packing Machine

Customized Irregular Bag Packaging Machine, Automatic Liquid Pre-made Bag Packaging Machine

-

Liquid Packing Machine

Automatic Liquid Paste Water Bag Filling Packing Machine

-

Liquid Packing Machine

Automatic Weighing 1kg 5kg Ice Cube Bag Packing Machine

-

Liquid Packing Machine

1kg Automatic Ice Cube Ice Block Ice Tube Bags Packaging Packing Machine