Customized PETG Extrusion Blow Molding Machine for PP, PE, HDPE, and PVC Plastic Bottles (500ml, 1L, 5L, 10L)

| ITEM | VALUE |

| Voltage | 380 V, 110 V, 415 V, 440 V, 220V, Customization based on customer needs |

| Output (kg/h) | 35 |

| Automation | Automatic |

| Power (kw) | 23.61 |

| Weight (kg) | 1500 |

| Screw L/D Ratio | 22 |

| Screw diameter (mm) | 45 |

| Clamping Force (kN) | 29.42 |

| Place of origin | China |

| Core components | PLC, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump |

| Plastic processed | HDPE , PP, PC, ABS, PVC, PE, EVA, PA, ABS/PP |

| Dimension(l*w*h) | 2.46*1.65*2.18m |

| Key selling points | Automatic, High Safety Level, High Rigidity, High-Accuracy, Multifunctional, Easy To Operate, Eco-Friendly, Flexible Manufacturing |

| Customized | Customization supported |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

This model is the smallest blow molding machine, characterized by its small size, high speed, stability, and energy efficiency. It can be equipped with automatic bottle neck degreasing devices, rotary bottle neck cutting devices, conveyor belts, and automatic crusher systems. Single-die, double-die, triple-die, quadruple-die, and six-die head options are available, with a daily output (24 hours) of approximately 20,000-120,000 units; it can produce plastic hollow products ranging from 0.01 to 1.8 L.

Control System

1. Real-time monitoring function for displaying mechanical actions;

2. 100-point blank wall thickness control, arbitrarily settable;

3. Analog signal accuracy reaches 16 bits;

4. Displays the cycle time required for full automation;

5. Displays real-time fault alarm information and causes;

6. Displays and modifies electric heating, temperature values, preheating values, high and low temperature alarms, etc.;

7. Includes multiple action safety interlock functions;

8. Parameters can be set and viewed directly on the operation screen;

9. Can display multiple languages, such as English, Spanish, and Chinese;

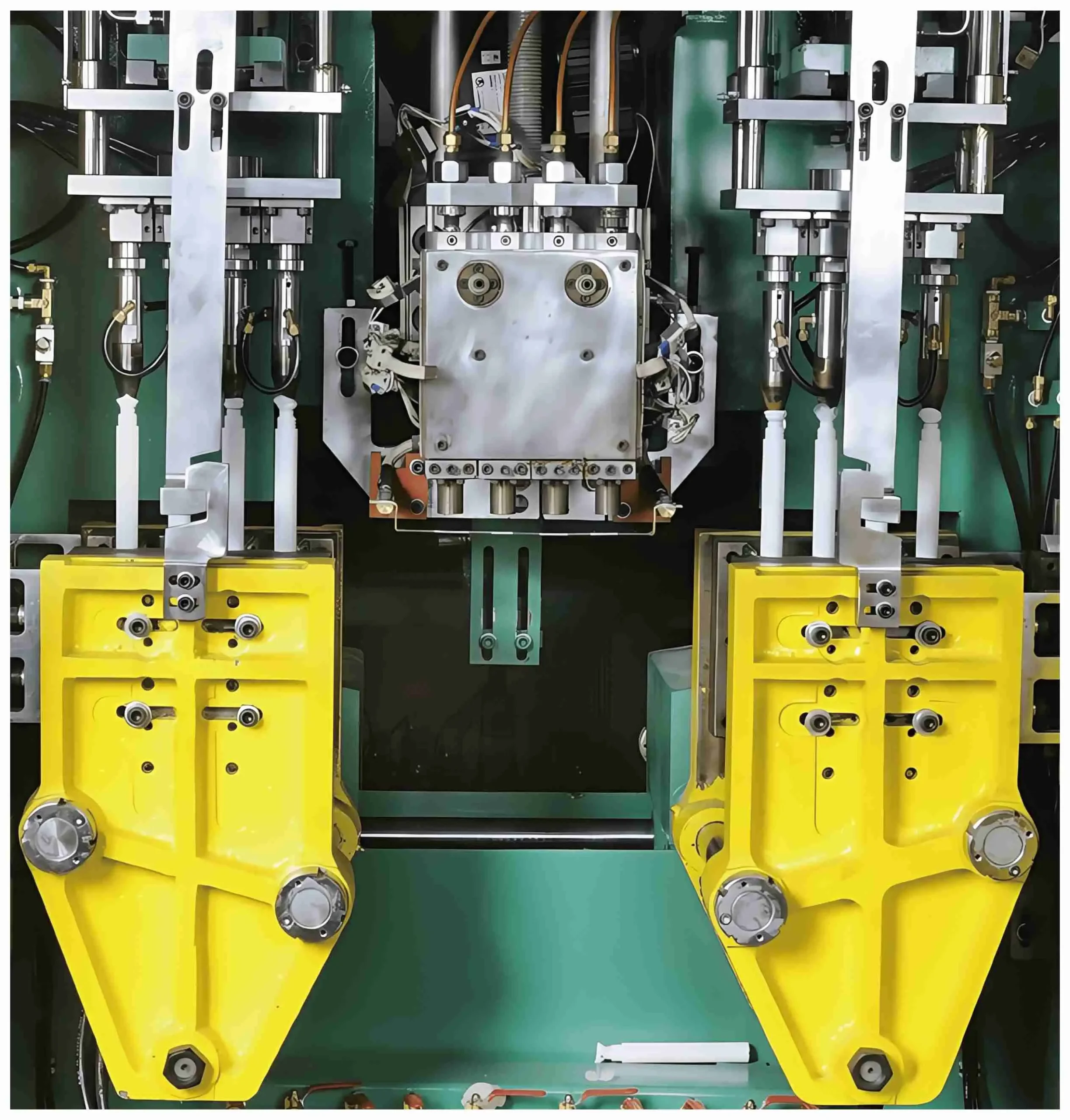

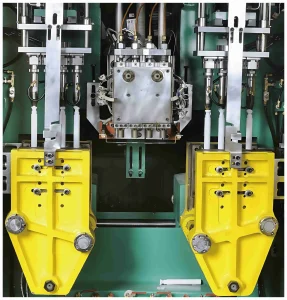

Locking Structure

The locking mechanism is designed to allow for the installation of molds of different thicknesses and to easily adjust the opening and closing stroke of the mold.

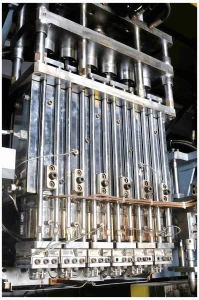

Optimized Die Heads

1. Multi-channel die heads have a smaller center distance, accommodating more cavities;

2. Utilizing center-feed flow guides and core-complementary flow channels, the blank wall thickness is uniform, and color change is rapid, supporting single-layer to six-layer co-extrusion to meet diverse user needs;

3. All die head types are equipped with a die wall thickness control system and adjustable ports and core bars, optimizing product wall thickness and saving plastic raw materials;

4. All dies can be equipped with a visibility device;

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

Extrusion Blow Molding Machine

Customized 220L 3-layer Double-ring Barrel High-density Polyethylene Extrusion Blow Molding Machine

-

Extrusion Blow Molding Machine

Customized 220L Single-layer Double-ring Chemical Roller Extrusion Blow Molding Machine

-

Extrusion Blow Molding Machine

Customized IBC Container Extrusion Blow Molding Machine, IBC Double-layer Extrusion Blow Molding Machine

-

Extrusion Blow Molding Machine

Customized Bleach Bottle Extrusion Blow Molding Machine, 3L Plastic Detergent Container Automatic Blow Molding Machine

-

Extrusion Blow Molding Machine

Customized All Seasons Sports Bench Chair Durable Comfortable Eco-Friendly Blow Molded Stadium Seats Big Discount Price

-

Extrusion Blow Molding Machine

Customized IBC Can Extrusion Blow Molding Machine HDPE 1000L Extruder

-

Extrusion Blow Molding Machine

Customized Automated Blow Molding Machine for Double HDPE 250ml, 300ml, 500ml, and 1000ml Chemical Bottles