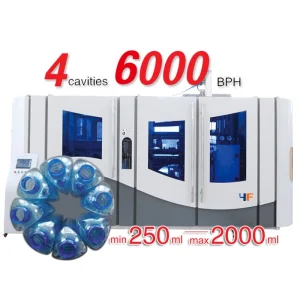

Customized Stretch Blow Molding Machine for PET 500ml and 600ml Cola Bottles

| ITEM | VALUE |

| Max.bottle diameter(mm) | 110 |

| Voltage | Customized |

| Clamping force (kn) | 200 |

| Plastic processed | PET |

| Weight (kg) | 7000 |

| Automation | Automatic |

| Warranty | 1 years |

| Neck diameter(mm) | 30 |

| Place of origin | China |

| Max.bottle height(mm) | 350 |

| Dimension(l*w*h) | 6200*1750*2600mm |

| Core components | PLC, Gearbox, Motor |

| Key selling points | High Productivity |

| Cavity | 7 cavities |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

High-Speed Automatic Blow Molding Machine

Equipment Performance Description and Features:

- The machine adopts a continuous rotation system with multiple safety protection devices to ensure high-speed preform feeding;2. The rotary transmission system makes construction and maintenance easier, reducing spare parts replacement costs;

- The compact preform heating distance design achieves efficient heating and reduces energy consumption;

- Water directly passes through the heating channel with an air-cooling system, protecting the preform neck from deformation;

- Optimized oven airflow and preform surface cooling, and a reversible heating box make lamp replacement easier;

- Mold closing adopts CAN linkage, without chain plate pins, small size, and long lifting distance;

- Hard claws grip the preform and bottle, resulting in a long service life;

- Servo motors are used to move the preform into the mold, ensuring high speed and accurate positioning. 9. Servo motors drive the drawing and blowing station, equipped with high-speed precision blowing valve assemblies to meet high production requirements;

- Servo motor for moving preforms into the mold, ensuring high speed and accurate positioning;

- Servo motor for driving the drawing and blowing station, equipped with a high-speed precision blowing valve assembly to meet high production requirements;

- Stainless steel tubing for cleaner, pollution-free blowing;

- High-pressure recovery system reduces power consumption;

- Bottle mold sliding makes installation easier;

- Multi-directional positioning of the automatic loading machine makes installation more flexible;

- Touchscreen control system, simple operation, 9-inch LCD screen;

- Transfer section using preform support can be used for different types of neck bottles;

- The finishing device is fixed to the machine to reduce machine space;

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

Stretch Blow Molding Machine

Customized Light Bulb Stretch Blow Molding Machine Cover LED High-speed One-step Blow Molding Machine

-

Stretch Blow Molding Machine

Customized Sports Water Bottle Stretch Blow Molding Machine, One-step Injection Stretch Blow Molding Machine

-

Stretch Blow Molding Machine

Five gallon blow molding machine, All computer control program

-

Stretch Blow Molding Machine

High speed automaticblow molding machine

-

Stretch Blow Molding Machine

High-speed special-shaped blow molding machine