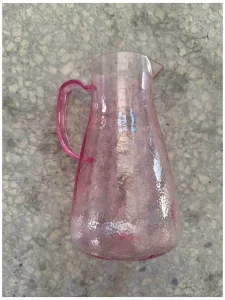

Customized Teapot Stretch Blow Molding Machine, 2-cavity Semi-automatic Blow Molding Machine with Handle

| ITEM | VALUE |

| Max.bottle diameter(mm) | 200 |

| Voltage | 380 V, 220 V |

| Clamping force (kn) | 100 |

| Plastic processed | PC, PP, PET, HDPE/PP |

| Weight (kg) | 500 |

| Automation | Semi-Automatic |

| Warranty | 1.5years |

| Neck diameter(mm) | 55 |

| Place of origin | China |

| Max.bottle height(mm) | 350 |

| Dimension(l*w*h) | Main unit: 1.98*0.7*1.68 meters / Oven: 2.17*0.85* |

| Core components | PLC, MOTOR |

| Key selling points | Easy To Operate |

| Customized | Customization supported |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

Semi-automatic blow molding machine performance:

1. Advanced PLC for stable performance.

2. Allows the bottle to rotate automatically and simultaneously in the infrared preheater.

3. High adjustability, enabling the preheater to preheat preforms of different shapes by adjusting the length of the light tube. Features an automatic temperature control device in the preheating zone, a reflector, and a constant temperature within the preheater.

4. High safety with automatic locking devices in each mechanical action, ensuring a safe operating state in case of malfunctions.

5. Pollution-free and low-noise operation using cylinder-driven actions instead of oil pumps.

6. Distributes blowing and mechanical action into three parts to meet different atmospheric pressures. Features a pneumatic pressure diagram for the machine’s components.

7. Powerful clamping force with high pressure and a double-crank connecting rod to lock the mold.

8. Operation: Manual.

9. Safe, reliable, and unique valve position design makes the machine’s pneumatic pressure diagram easier to understand.

10. Low cost, high efficiency, easy operation, and convenient maintenance. 11. Prevents bottle contamination.

12. Ideal cooling effect for bottle molds using a cooling system.

13. Easy to install and start.

14. Low rejection rate: less than 0.2%.

15. Manual labor saving; one person is sufficient to operate the machine.

16. Adopts a new double-bent arm and four-bar clamping structure (patented): Lateral movement; the middle mold plate moves parallel; the distance between the two mold plates is adjusted by a sprocket. Therefore, the clamping force is very strong.

17. Energy-saving design, which can increase your profits.

18. Separate air control system designed to avoid waste contamination.

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

Stretch Blow Molding Machine

Customized Six-cavity Blow Molding Machine with Automatic Small Neck

-

Stretch Blow Molding Machine

Custom-made Wide-mouth Can Blow Molding Machine, 2-cavity, 1200-1500 Bph, 0.1-2L Blow Molding Machine

-

Stretch Blow Molding Machine

Five gallon blow molding machine, All computer control program

-

Stretch Blow Molding Machine

High speed automaticblow molding machine

-

Stretch Blow Molding Machine

Semi-automatic blow molding machine