CVP Everest Cartoning Machine A Perfect Box Every 3 Seconds, Carton machine, Cartoner machine Carton packing machine, Source Factory, Super Low Discount Price

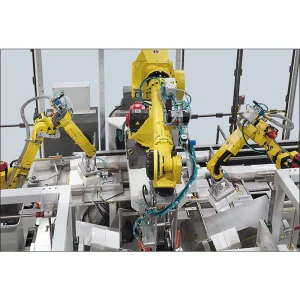

An automated packaging machine with the best performance in the industry.

One fit-to-size box every 3 seconds

Our CVP Everest Cartoning Machine stands out as the ultimate automated packaging machine, modernizing your fulfillment chain. Experience less stress, lower costs, and reduced waste while gaining more control, capacity, and speed. It’s the ultimate efficiency booster.

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

CVP Everest Cartoning Machine: Produces a Perfect Carton Every 3 Seconds

One, Two, or Three Corrugated Paper Feeders

- One, two, or three continuous corrugated paper feeders use fan-folded material for dynamic switching and replenishment, reducing inventory and saving usage.

- This cartoning machine allows millions of unique carton size combinations. We do not accept any corrugated paper suppliers.

- Each CVP carton machine supports up to 3 unique brands of corrugated paper designs.

Import Stations

- Single or dual import stations support high operator and machine productivity levels.

- The operator scans a unique order barcode and places it on the input conveyor belt.

Automatic Feeding

- Universal automatic connection between the upstream warehouse and CVP. Single-piece orders are automatically imported into CVP.

- Optimizes CVP throughput.

- Eliminates reliance on labor.

- No human errors.

Basic Constructor

- Our scanners capture 3D images of each unique package to determine the required minimum carton size.

- The corrugated paper is cut and scored, forming the carton which is erected around the package. The carton bottom is fixed with hot melt glue and transferred via conveyor to the lid maker.

- On-demand construction allows the creation of various sized cartons without WMS data.

Pick Carton/Prepack

- Use our bottom maker to create an empty pallet.

- Collect the order using the bottom.

- Close the bottom with a lid.

Lid Maker

- Two lid applicators work in parallel, fully sealing each custom carton with hot melt glue on all four sides.

- The corrugated paper is cut and scored to form the smallest lid size required for the carton bottom, creating a sturdy, fully sealed carton.

Tear Strip

- Optional tear strip for easy customer access to the package.

Weighing Station

- Order weight verification through an inline scale optimizes rate shopping, ensuring the weight and size of each package are accurate.

Label Printing and Application

- Create and apply labels that meet carrier requirements, ensuring accurate delivery.

Additional Printing and Application

- Additional printing and application systems can add another label to any package.

- Labels can be applied for internal logistics processes or to comply with local and/or global regulations.

Custom Packaging Box Printing

- Create a unique experience by adding the customer’s name, package details, or your brand.

- After box creation, use inkjet printing for customization, including seasonal, promotional, special offers, or other information.

Still struggling to choose the right packaging machine?

Not sure where to source the filling machine?

Worried about after-sales support after purchasing an automatic packaging machine?

Concerned that the packaging line price is too high?

As a packaging machine manufacturer with 20 years of manufacturing experience, Liuzhoume’s product range covers: packaging machines, vacuum packaging machine, stand-up pouch packaging machine, pouch packaging machine, palletizing machine, package sealer machine, gluing machine, adhesive machine, flow machine, granulating machine, liquid machine, pharmaceutical machine, powder machine, pouch filling machine, sachet packaging machine, and various other packaging equipment and packaging lines.

We offer both semi-automatic and automated packaging machines, and if you have special packaging requirements, such as needing a custom packaging machine, we have an experienced team of packaging machinery R&D engineers ready to tailor a packaging solution based on your product characteristics.

As a source factory, we have strong industrial resources and can greatly reduce the manufacturing cost of packaging machines and filling machines through resource integration. By contacting us directly, you can get satisfying super-low wholesale prices!

No need to worry about post-purchase warranty issues. As a powerful packaging machine supplier, Liuzhoume has long-term deep partnerships with local distributors who can provide after-sales support!