Fruit Box Injection Stretch Blow Molding Machine Manufacturer

| item | value |

| Plasticizing capacity(g/s) | 1627 |

| Injection weight (g) | 1627 |

| Style | Horizontal |

| Injection rate (g/s) | 499 |

| Weight (kg) | 14500 |

| Plastic processed | PP, PC, ABS, PE, PVC, PET |

| Warranty | 1.5 year |

| Mold height(mm) | 280mm – 330mm |

| Screw speed (rpm) | China |

| Screw heating power(kw) | 1rpm – 160rpm |

| Distance between tie bars | 725*725mm |

| Key selling points | Energy Saving |

| Core components | PLC, Motor, Engine, Gear |

| Customized | Customization supported |

- Fast Shipping

- Support OEM&ODM

- TOP Quality

- Professional Service

DESCRIPTION

Product Description

Hot-selling Plastic Crate Injection Molding Machine, Fruit Box Manufacturing Machine

We supply a wide variety of injection molding machines from 50T to 3000T, including color chip manufacturing machines, energy-saving injection molding machines, gear manufacturing machines, double transparent color injection molding machines, bakelite injection molding machines, PET preform injection molding machines, quantitative pump and variable pump injection molding machines, PVC parts injection molding machines, etc.

Injection Molding Machine Features:

Injection Molding Machine Features:

→ Larger space between tie rods

→ Central clamping structure

→ High-quality components

→ Energy-saving servo motor

→ Low noise, fast response

→ High precision, stability, and ultra-long lifespan

→ T-slot pressure plate

→ Abundant spare parts

→ Better price

Clamping Unit:

1.) Optimized pressure plate design with high rigidity and increased space between tie rods

2.) Based on the pressure plate layout, with T-slots and head holes, the positioning design in the moving pressure plate better adapts to various molds

3.) New ejection system design with longer ejection stroke, larger space, and better rigidity

4.) Hydraulically driven gear-type mold height adjustment mechanism

5.) Mechanical safety interlock repositioning for easy operation

Injection Unit:

1.) High-quality linear motion guides ensure smooth and accurate injection process

2.) High-speed, high-pressure injection structure improves injection speed

3.) Dual-nozzle cylinders ensure a more uniform and stable structure.

4.) Professional screw barrel design for various tools.

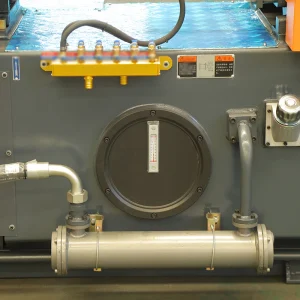

Hydraulic System:

1.) Dual proportional composite valve controls system pressure and flow, highly sensitive and stable.

2.) Imported high-quality pump, low noise, long life, and stable performance.

3.) Optional world-renowned servo hydraulic system, offering better performance in terms of lower noise and energy saving.

4.) Servo system provides precise feedback control of pressure and flow, with higher sensitivity and more accurate repeatability.

5.) High-performance hydraulic valves, fewer malfunctions, fast switching, and convenient maintenance.

6.) Low-pressure mold protection system, more suitable for precision molds.

Company Profile

Our main products are industrial equipment, including packaging machinery, filling machines, rubber machinery, and machine tools. We have our own production workshop and can provide a one-stop service from design, mold making, sampling, testing, production to export. We also offer free on-site installation, a 2-year free warranty, a 24-hour local service team, and product customization support. Furthermore, we plan to recruit distributors in several countries. We provide the products and customer resources, while distributors provide store locations and assist with after-sales issues.

FAQ

- Who are we?

We are located in Fujian, China. Since 2024, our products have been sold to North America (30.00%), Western Europe (10.00%), Southeast Asia (10.00%), South America (7.00%), Southern Europe (5.00%), Northern Europe (5.00%), Central America (5.00%), Eastern Europe (5.00%), East Asia (5.00%), the Middle East (5.00%), Oceania (5.00%), South Asia (5.00%), and Africa (3.00%). We have approximately 101-200 employees in our office.

- How do we guarantee product quality?

We always provide pre-production samples before mass production;

We always conduct final inspections before shipment;

- What can you buy from us?

Packaging machinery, filling machines, rubber machinery, machine tools, etc.

- Why choose us instead of other suppliers?

With 20 years of design and R&D experience, we are one of the largest equipment manufacturers in China. We mainly produce industrial machinery, including packaging machinery, filling machines, rubber machinery, and machine tools.

- What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express, DAF, DES;

Accepted Payment Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF;

Accepted Payment Methods: Wire Transfer (T/T), MoneyGram, Western Union, Cash;

Languages: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian

Related products

-

Injection blow molding machine

Customized Irregular Bottle Blow Molding Machine, Automatic Plastic Blow Molding Machine

-

Injection blow molding machine

Customized Dropper Blow Molding Machine, Cosmetic Polypropylene Bottle Making Machine, Medical Bottle Making Machine