I. Introduction

The protein powder market is growing at an extremely fast pace. According to data, by 2030, the global sports nutrition market is expected to reach $85 billion, with protein powder being a major component. As consumers’ health awareness increases and the demand for sports nutrition products rises, this figure will grow even larger.

With this opportunity, many individuals and businesses have entered the protein powder industry. Choosing the right protein powder packaging machine and suitable travel containers for powder supplaments will be key factors in determining the success of your protein powder business.

As a manufacturer with over 20 years of experience in packaging machines, Liuzhoume (official website: www.liuzhoume.com) has summarized its rich manufacturing experience to bring you this protein powder packaging guide. It will help you select the most suitable powder filling machine and protein powder container for your needs.

II. How to Choose Protein Powder Packaging Containers?

Protein powder packaging containers are diverse. To make a choice, you need to consider various factors, such as shelf display appeal, transport convenience, airtight storage, and ease of use. You must balance consumer satisfaction with practical needs. Below are some common packaging container types, along with their pros and cons:

1.Plastic Jars

Plastic jars for protein powder generally have a wide-mouth design.

Advantages:

- Large capacity and easy-to-open lids, convenient for long-term use without frequent purchases.

- Ideal for bulk protein powder packaging, reducing costs with a lower unit price than travel-sized containers for powder supplements.

- Seamless wrap-around labels enhance shelf appeal and product information display.

Disadvantages:

- Frequent lid opening may compromise airtightness, increasing the risk of moisture and dust contamination.

- Requires careful storage or rapid consumption to maintain quality.

2.Tapered Neck Bottles

These bottles have a narrowed neck and screw caps, similar to vitamin packaging.

Advantages:

- Projects a professional, health-focused appearance, resembling health supplement packaging.

- Offers better airtightness than wide-mouth jars.

- Convenient for protein powder containers for travel, ideal for portability.

Disadvantages:

- Higher production costs.

- Limited capacity, less suitable for consumers requiring larger quantities.

3.Pouch Packaging

Pouch packaging is a cost-effective option preferred by many gym-goers.

Advantages:

- Lightweight and easy to fit in gym bags.

- Resealable pouch designsensure repeatable airtightness for easy preservation.

Disadvantages:

- Difficult to pour without risking spillage.

- Less durable than jars, increasing the chance of damage during transportation.

4.Metal Cans

Metal cans are a premium option for protein powder packaging.

Advantages:

- Premium look enhances product perception of quality.

- High durability and impact resistance during transportation.

- Superior airtightness compared to other options.

Disadvantages:

- Heavy and less practical for portable protein powder containers.

- High production costs.

- Prone to scratches or dents during rough handling, affecting aesthetics.

Liuzhoume.com reminds you that no single packaging container is perfect. Evaluate the pros and cons carefully to choose the best solution for your protein powder packaging line.

III. How to Extend Protein Powder Shelf Life

The main factors affecting protein powder shelf life are packaging materials and storage conditions. It is unrealistic to expect consumers to store their protein powder in ideal environments with controlled temperature and humidity. Thus, working with packaging machine suppliers to develop consumer-friendly food packaging equipment and techniques ensures longer shelf life and builds customer trust.

1. Airtightness of Containers

For a successful protein powder brand, investing in quality protein powder packaging containers is essential. Opt for airtight containers made from heat- and moisture-resistant materials to enhance durability and freshness.

2. Nitrogen Flush Packaging

Nitrogen flush packaging is a highly effective method to prolong protein powder shelf life. By removing oxygen, it reduces oxidation and microbial activity. Nitrogen, being natural and safe, ensures no chemical contamination while also being environmentally friendly. This process is often integrated with automated packaging machines for seamless production.

3. Single-Serve Sachets

Single-serve sachets are an innovative way to package protein powder in precise, individual portions. They are also the best way to travel with protein powder, offering convenience and portability.

- Advantages:

- Eliminates the guesswork of portioning protein powder.

- Isolates air, light, and moisture effectively, keeping the contents fresh.

- Ideal for travel, as these powder supplement travel containers are compact and easy to carry.

- Conclusion:

Single-serve sachets are the best choice for maintaining freshness and convenience, ensuring that only one sachet is opened at a time while others remain sealed.

IV. What Equipment is Used in the Protein Powder Packaging Production Line?

A fully functional protein powder packaging production line incorporates several machines for efficient and high-quality packaging.

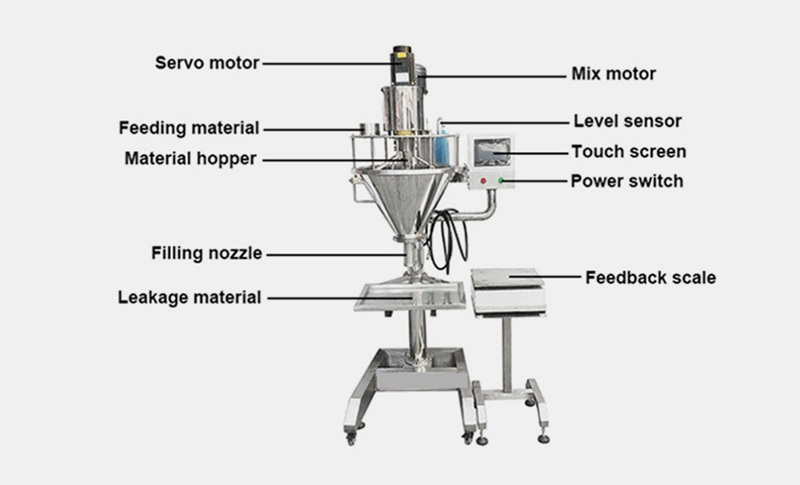

1. Protein Powder Filling Machine

This machine is vital for accurate and efficient filling. Two main options are available:

Volumetric Filling Machine:

Ideal for precise measurements, it ensures consistent filling with minimal errors. It is compatible with a range of containers, from plastic bottles to flexible packaging bags, and supports various materials like metal, paper, and PET.

Automatic Powder Filling Machine:

Designed for large-scale production, this machine ensures rapid, hands-free filling. It significantly enhances productivity while minimizing errors, making it an excellent choice for high-volume operations.

2. Protein Powder Sealing Machine

A protein powder sealer machine securely seals containers to keep the product fresh and protected.Sealing is crucial for maintaining freshness and preventing contamination. Two popular sealing methods for protein powder are:

- Foil Sealing:Ensures sterile packaging.

- Nitrogen Sealing:Extends shelf life by reducing exposure to oxygen.

3. Protein Powder Capping Machine

This machine automates the capping process for containers, improving efficiency and hygiene. It works with various cap styles, including screw and twist caps. Depending on production needs, semi-automatic and automatic packaging machines are available.

4. Protein Powder Labeling Machine

Manual labeling is impractical for large-scale production. An automated labeling machine is faster and more consistent. Options include pressure-sensitive labeling machines for caps and body labels.

Building a Complete Protein Powder Packaging Line

By combining industrial packaging machines like filling, sealing, capping, and labeling machines, you can create a fully automated production line. This boosts efficiency, ensures precision, and supports large-scale production. Liuzhoume.com highlights the importance of leveraging complementary machines to achieve high-quality protein powder packaging that meets modern market demands.

V. Liuzhoume – A Packaging Machine Manufacturer with Over 20 Years of Experience

Liuzhoume.com is a Chinese factory with over 20 years of experience in manufacturing packaging machines. As part of a leading industrial manufacturing country, we excel in resource integration and leverage the innovative capabilities of our professional engineering team. This has made our packaging equipment a leader in the industry, with products exported to the United States, Southeast Asia, the Middle East, and other regions.

Our extensive research and development in industrial packaging machines ensure top-tier quality and innovation. Liuzhoume.com offers a wide range of equipment, including:

- Powder packaging machines

- Automatic filling machines

- Vacuum packaging machines

- Stick packaging machines

- Filling and capping machines

- Packaging sealing machines

- Automated packaging machines

- Pouch filling machines

Additionally, our lineup features food packaging machines, protein powder filling machines, and complete packaging lines for streamlined production. For specific needs beyond our catalog, we can utilize our network to source or recommend tailored solutions.

Customized Protein Powder Packaging Solutions

Liuzhoume.com specializes in one-stop customization services, offering bespoke solutions for protein powder packaging. Whether you require vacuum packagers, protein powder containers for travel, or automatic powder filling machines, we ensure every detail aligns with your unique requirements.

Visit our official website at www.Liuzhoume.com for further information and inquiries.

VI. Conclusion

The growing consumer base for protein powders now extends beyond fitness enthusiasts to include health-conscious individuals. This rising demand presents significant profit opportunities but also challenges in achieving packaging efficiency.

By investing in high-quality packaging machines and protein powder filling machines, manufacturers can enhance their competitive edge and deliver reliable, innovative solutions to meet market demands. Liuzhoume.com stands ready to support your success with its advanced packaging equipment and tailored solutions.