I. Introduction

The global demand for canned products is on the rise. In 2019, the global canned food market size was $91.9 billion, and industry forecasts predict that this figure will reach $111.13 billion by 2032. Businesses with commercial insight have already recognized this market potential. Whether they are startups or global giants, they are investing heavily in commercial canning equipment and packaging machines.

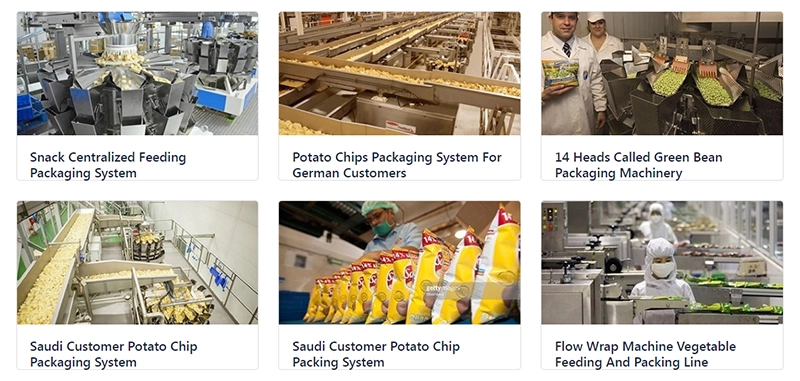

With over 20 years of experience in packaging and filling machine manufacturing, liuzhoume (official site: www.liuzhoume.com) has gained rich industry expertise through long-term cooperation with clients and packaging machine suppliers. In this article, liuzhoume.com will provide an in-depth analysis of the vast world of canning equipment, helping you choose the best packaging line based on your scale and products!

II. What Canning Equipment Is Available?

Before choosing canning equipment, liuzhoume.com advises understanding the range of equipment available:

1.Main Equipment

Can Filling Machine

The filling machine is one of the most crucial pieces of equipment in the entire packaging line. Its quality and efficiency determine product quality and production efficiency. We all know that the most important aspect of canned products is filling accuracy. A can filling machine ensures that each container is filled to the required amount and level. Some filling machines can fill multiple containers at once, greatly improving production efficiency.

Can Seaming Machine

The importance of a seamer can machine is unquestionable as it affects product safety and sealing quality. For canned foods that need long-term storage, it effectively extends shelf life and prevents contamination. This is critical for both businesses and consumers, as no one wants to purchase a leaking or spoiled can. Seaming machines come in rotary and non-rotary types. Rotary seamers are typically used in automated filling machines for large-scale production, while non-rotary seamers, which only rotate the seamer head, are better suited for liquid filling to prevent spillage.

2.Other Equipment

Although liuzhoume.com classifies the following products as “other equipment,” they are, in fact, essential for the entire canning machinery line:

Capper

A capper functions similarly to a sealing machine by sealing bottles or containers. However, it is primarily used in food packaging equipment lines for bottled products, such as beverages, condiments, and pharmaceuticals. Seamer machines, on the other hand, are used more for aluminum or metal cans to create an airtight seal.

Labeling Machine

A labeling machine attaches labels to product containers, aiding product identification, attracting consumer attention, enhancing brand recognition, and providing important product information for consumers to make purchasing decisions. Most importantly, a product without a label would not meet regulatory requirements, making a labeling machine indispensable for any packaging line.

Coding Machine

A coding machine prints production dates, batch numbers, barcodes, etc., on products or packaging. In liuzhoume.com’s 20-plus years of working with clients, no client has gone without a coding machine. It marks crucial information like production dates, expiration dates, and source materials onto barcodes or QR codes. Industry data shows that over 85% of consumers prefer products with clear production and expiration dates, underscoring the importance of coding machines for your products.

Can Cleaning Machine

A can cleaning machine is used to clean and remove impurities from the interior and exterior of cans, ensuring they are hygienic before filling. In industries such as food and pharmaceuticals that maintain high hygiene standards, can cleaning machines are crucial for product quality and directly affect a company’s reputation. It is key to gaining consumer trust and positive feedback. For businesses focused on high hygiene and quality, partnering with an experienced packaging machine manufacturer or packaging machine supplier like liuzhoume.com ensures access to reliable equipment and expert support.

III. Assessing Your Needs

Assess Your Production Capacity

Before purchasing canning equipment, assess your production goals and packaging needs. Consider not just “current needs” but also forecast your production goals and packaging methods for the next 1-3 years.

If you are a small-scale producer of a single product, a small filler machine might be more suitable, and you may not need all equipment for an entire packaging line. Some steps can be performed manually. Nevertheless, when choosing a filling machine, consider its scalability to accommodate future production expansion.

If you are a large-scale producer of multiple products, seek experienced packaging equipment manufacturers like liuzhoume.com to tailor complex, efficient canning machinery solutions for you.

Assess Your Budget

Purchasing canning equipment should be within your means. While quality improvement is necessary, it should not come at the cost of financial strain. Your budget limits your choices. Finding a balance between quality, efficiency, and cost is wise when selecting the right food packaging machine.

Special Customization Needs

Do you need to fill products while stirring? Are your packaging containers irregularly shaped? Standard packaging machines might not suit you. This calls for manufacturers with customization capabilities, like liuzhoume.com, to create custom packaging machines tailored to your packaging needs.

IV. How to Choose the Right Filling Machine for Your Canning Line

Product Specifications

With over 20 years of experience in manufacturing filling machines and packaging equipment, liuzhoume.com sums it up in one phrase: the product determines the machine!

- Nature of the Product: If your product is liquid or powder, it’s easy to distinguish—each suits liquid filling machines or powder filling machines, respectively. However, if your product is a viscous paste that may require heating, stirring, or sterilization, only a specialized paste filling machinewill suffice.

- Container Material: Plastic, metal, and glass containers each require different types of packaging equipment or filling machines.

- Filling Volume and Accuracy: High-capacity products need large-volume filling machines, while precise filling requires high-accuracy quantitative filling machines.

- Special Handling Needs: Fragile products prone to damage during filling require a gentle operation filling machine. For instance, jams with whole fruits can be crushed by standard machines but remain intact with a low-pressure, gentle filler machinethat preserves texture and taste.

Production Capacity

Production output dictates the speed of the filling equipment. For high-volume needs, a fully automated filling machine is recommended. Liuzhoume.com offers top-tier machines with speeds up to 60,000 cans per hour, ideal for large-scale production. For medium or smaller outputs, semi-automatic filling machines are more cost-effective.

Liuzhoume.com advises against the unnecessary pursuit of maximum speed for small and medium-sized businesses. Balancing cost and production speed is the optimal approach to boosting efficiency.

Product Compatibility

Consider whether the filling machine is adaptable to various containers and volumes or can be modified to handle different products by changing specific components.

Initial and Maintenance Costs

Evaluate both the initial investment and maintenance expenses of the filling machine. Also, factor in spare part purchases and future expansion costs.

Degree of Automation

Not all businesses benefit from fully automated packaging lines. For high-volume production, automated machines can significantly reduce production costs and improve efficiency.

For smaller-scale operations, if the cost analysis between automated equipment (including initial and maintenance costs) and manual labor shows that labor is cheaper, semi-automatic or manual machines may be a better fit.

Facility Layout

In addition to considering the footprint of the filling equipment, allocate space for potential future expansion.

V. Recommended Experienced Filling Line Manufacturer: liuzhoume

Reliable Technical Service

Liuzhoume.com offers advanced technology that quickly adapts to production needs, ensuring swift adjustments and meeting the demands for filling and packaging machines. Our high-quality products boast a service life far exceeding industry standards, supporting stable production.

Extensive Experience to Avoid Potential Issues

Liuzhoume.com has accumulated significant expertise through numerous projects, providing detailed service and advice that addresses overlooked issues and mitigates potential problems, minimizing downtime and maximizing production efficiency.

Custom Solutions for Special Requirements

Liuzhoume.com offers tailor-made packaging solutions, verified and optimized to suit your product and production needs, ensuring seamless integration with your packaging line.

Industry Resources and Network

As one of China’s top packaging machine manufacturers, liuzhoume.com maintains long-term partnerships with many collaborators and is well-connected with related industry manufacturers. If your needs extend beyond our product range, we can provide comprehensive services through our network or refer you to trusted partners.

VI. Conclusion

The demand for canning machinery is on the rise, and its complexity and technological advancements are evolving. As the industry progresses, companies will increasingly rely on professional filling equipment solutions.

As a leading manufacturer of packaging and filling machines in China, liuzhoume.com offers top-quality filling products and practical advice, helping businesses stand out in a competitive market.