I. Introduction

The global spices and seasoning market was valued at $27.5 billion in 2023, and it is projected to grow from $28.72 billion in 2024 to $42.27 billion by 2032. As spices are essential household condiments, their ability to enhance the flavor, color, and aroma of food is irreplaceable, making the spice market one of the few industries that has never experienced a decline.

The consistently growing spice market has become one of the most sought-after industries for spice vendors and spice packaging companies. Numerous spice brands are competing to capture a larger market share. In such fierce competition, how to pack spices in a way that stands out is a key issue that packaging manufacturers and vendors who wholesale spices for resale should pay attention to.

Liuzhoume (website: www.liuzhoume.com), a packaging machine manufacturer with over 20 years of experience, has compiled this guide. We will answer your questions comprehensively, from spice packaging containers to spice powder packaging machines, to help you choose the right packaging container and machine.

II. Types of Packaging

Spices are highly sensitive to air and moisture. A good spice packaging container can isolate air and moisture, keeping the spices dry and clean. In contrast, incorrect packaging can cause the spices to lose their flavor and aroma quickly. Therefore, when choosing spices packaging, businesses should select the right spice packaging container according to their product.

1. Spice Cans

Spice cans come in a variety of materials, with metal being the most common. The market generally uses steel or aluminum cans, which are treated with anti-rust processes to enhance durability. These metal cans are also highly resistant to impact, making them less likely to break upon collision. They typically feature screw-on lids or sealer vacuum packaging machine systems, ensuring excellent airtightness. This helps maintain the dryness and seal of the spices inside, preserving their flavor and aroma.

However, metal cans have their drawbacks. They should be stored in a cool, ventilated area, as direct sunlight can increase the internal temperature due to the strong heat absorption of metal, leading to condensation and potential moisture damage to the spices.

2. Spice Bottles

Most spice bottles on the market are made of plastic or glass. These transparent materials allow consumers to immediately see the quality of the spices inside, making them suitable for display on store shelves. Both glass and plastic materials are highly customizable, allowing businesses to create unique shapes tailored to their brand, thus increasing the product’s attractiveness. Additionally, many bottles for herbs are filled using automated filling machines for precision and consistency.

However, these bottles also have some downsides. Glass bottles are costly and prone to breakage, while plastic bottles are not biodegradable. Compared to spice cans, bottles tend to have a smaller capacity.

3. Spice Bags

Spice bags are a flexible packaging option, often considered an environmentally friendly choice compared to rigid packaging. Common types include stand-up pouches, flat pouches, bottom gusset pouches, transparent pouches, spouted pouches, and kraft paper bags. These bags come in various shapes and materials, usually equipped with packaging sealing machines to ensure re-sealability, which helps slow down the loss of flavor.

However, bags may not be suitable for high-end packaging. If targeting premium consumers, unless the bag has an eye-catching and unique design, it may give the wrong impression about the brand image. For businesses, bulk options like spice packets wholesale are a cost-effective choice for distribution.

III. Unique Spice Packaging Designs That Make Your Business Stand Out

With the wide range of spice packaging products available, consumers may experience aesthetic fatigue. If you’re looking for a unique design to package your spices, consider collaborating with a professional spice packaging company. However, Liuzhoume.com wants to remind you that regardless of the design you choose, you should adhere to the following three principles:

1. Consistency with Brand Identity

When designing seasoning packaging, don’t just pursue uniqueness for its own sake. Avoid making the packaging design incompatible with your brand identity. The overall color scheme and pattern design of the packaging should remain in harmony with your brand’s tone.

Furthermore, to build a well-known spices brand, it is essential to display your logo in the most prominent position on the packaging. A catchy slogan that resonates with consumers can also create a strong market response.

2. Portability

Many people mistakenly think that packaging portability is only for travelers. In fact, for homemakers who frequently go on large grocery shopping trips, heavy spices packages can add to their burden. If portability is not achievable, consider making the packaging lighter. This is a more user-friendly and thoughtful design approach.

3. Re-sealable Design

As mentioned earlier, spices are highly sensitive to air and moisture, so the packaging must ensure excellent moisture-proof and airtight properties. If you opt for spice cans or spice bottles, pay special attention to the lid’s sealing capability to ensure it remains effective after repeated openings. If you’re using spice bags, choosing a sealed strip or zipper design is an excellent choice.

IV. Types of Spice Packaging Machines

There are many packaging machines and filling machines available for spice packaging. However, choosing the right one requires understanding the functionality of these devices to ensure you find a machine suitable for your product.

1. Spice Powder Filling Machine

This powder filling machine can fill spices into bags or bottles by predetermined weight or volume. It offers high precision and automation, reducing human error. Additionally, it accommodates various container sizes and specifications to meet diverse production needs. Notably, this machine is versatile, handling not only spices and herbs but also granules and liquids, making it applicable in the food, cosmetics, and pharmaceutical industries.

2. Herbal Granule Filling Machine

These granule filling machines come in both automatic and semi-automatic types. They can measure and fill granular spices or fine powder mixtures into containers. They also feature sealing systems for efficient sealing, preserving spice flavor. These machines integrate multiple steps, such as filling, weighing, and sealing, into one device, offering high efficiency for diverse packaging needs.

3. Sealing Machine

Sealing is crucial for spices to protect them from air and moisture. Choosing the right sealer machine is essential for maintaining product freshness. Sealing machines support various methods, such as heat sealing, capping, and vacuum sealing, ensuring freshness and protection against contamination. For special requirements like vacuum or gas flushing functions, consult the manufacturer for customization. Contact liuzhoume.com, a seasoned packaging machine manufacturer, for superior custom solutions.

4. Capping Machine

For spice products in jars, a capping machine is indispensable for efficiency. It seals jars to preserve the spice flavor and suits containers like glass jars or plastic bottles. Capping machines can function standalone or alongside filling machines and labeling machines, forming a complete packaging line to enhance automation and save labor costs.

5. Labeling Machine

A labeling machine is vital in spice packaging lines. It applies labels with key product information onto packaging containers flawlessly, reducing manual errors and increasing production efficiency.

6. Coding Machine

Coding machines do more than print QR codes; they are integral to modern business management. They assign a unique ID to each spice product, allowing both managers and consumers to quickly access product information. Coding machines are indispensable for inventory management and building consumer trust.

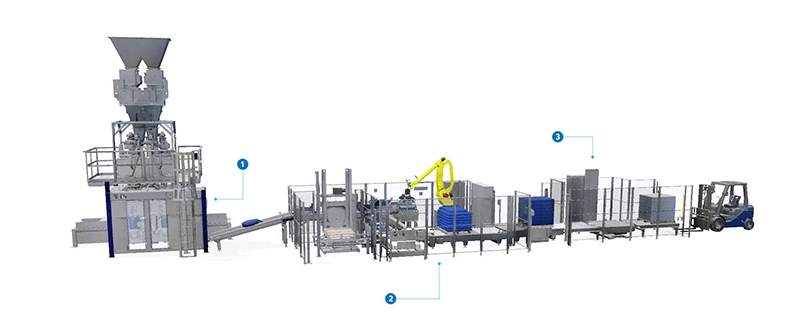

V. liuzhoume.com – Customized Spice Packaging Lines

A spice packaging line is a complex production process, from raw material handling (e.g., grinding, mixing) to precise filling, sealing, labeling, and coding. Using automatic packaging machines for just the filling part limits production efficiency. Modern enterprises often adopt complete automated packaging lines to streamline the entire process, accelerating production while reducing labor costs and errors.

liuzhoume.com has over 20 years of experience manufacturing packaging machines and filling machines. As China’s largest packaging machine supplier, we offer cutting-edge precision technology to provide the best packaging solutions for your business.

Whether you need a linear or rotary packaging line, liuzhoume.com can customize the machines to your requirements. We offer a full range of powder filling machines and granule filling machines, including spice powder packaging machines, milk powder packaging machines, protein powder packaging machines, and food packaging machines for rice, nuts, and more. Optional features like mixing or grinding are also available. Simply share your needs, and liuzhoume.com will make it happen.

VI. Conclusion

From liuzhoume.com’s extensive experience with spice manufacturers, the success of your spice product hinges on quality packaging. Premium seasoning packaging elevates brand image and consumer trust. Opting for cheap commercial spice packaging to save costs risks compromising product quality and relegating your business to the low-end market.

Investing in high-quality spice packaging machines and reliable sealing machines for packaging is essential for fast production, safe packaging, and overall productivity. For any spices packaging machine needs, contact liuzhoume.com today.