For small and medium-sized enterprises (SMEs) that require packing machines, choosing the right packing machine is crucial as it impacts the efficiency and operation of the entire packaging line. While business owners often focus on initial costs when selecting a pack machine, they frequently overlook total ownership costs, including installation environment, maintenance costs, and repair for packing machines.

I suggest that SME owners consider compact VFFS machines. In this guide, I will explain why a compact VFFS machine is suitable for you and help you learn how to choose the best packing machines to improve your production efficiency.

1. What is a Vertical Form-Fill-Seal (VFFS) Machine?

The packing machine, specifically the Vertical Form-Fill-Seal (VFFS) machine, is an automated packing machine system used for putting products into bags. It has distinct advantages in the packaging equipment industry where quick, reliable, and space-saving solutions are needed.

VFFS machines perform three critical functions: making bags from flat material, filling products, and securely sealing them. The “compact” version of VFFS provides a complete set of packaging functions, including those found in vacuum packing machines, within a smaller footprint, making it an ideal choice for facilities with limited space—one of the main reasons I recommend compact VFFS machines as they offer the efficiency of an automatic packing machine and are well-suited for pouch packing machine applications.

Although compact VFFS machines are smaller than standard machines, they encapsulate a full range of packing machine functions. These machines combine space optimization with operational efficiency, making them suitable for small production lines without sacrificing packaging speed or efficiency.

VFFS machines can accommodate various product types—whether powder packaging ideas or liquid, solid, or granular products—effectively packaging them with precise, airtight seals. Their versatility meets various industrial and commercial food packaging equipment needs.

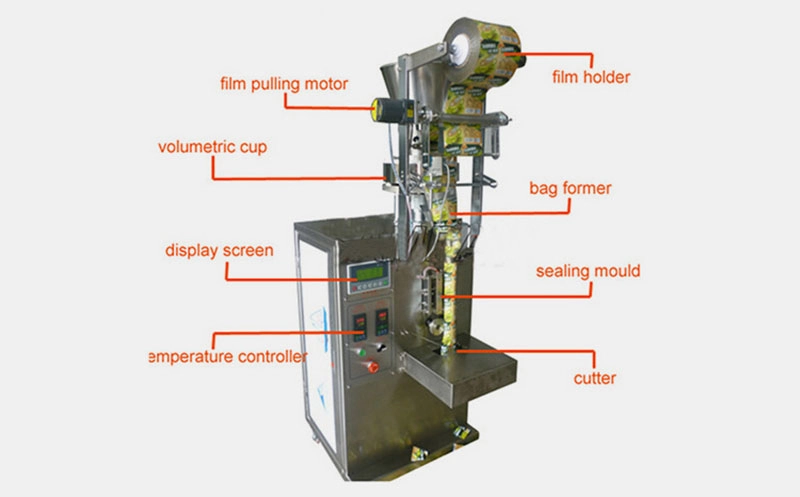

2. Components of VFFS Machines

Don’t overlook this aspect! Understanding the core components of a packing machine, especially automatic packing machines like VFFS, can significantly enhance production efficiency, operational knowledge, and troubleshooting ability, which is crucial for subsequent use and maintenance.

Core components include:

- Film unloading system: Stores and dispenses packaging materials, ensuring a continuous supply for the automatic packing machine.

- Forming tube and collar: Guides the film into a cylindrical shape, forming the basis for the packaging bags.

- Product filler: Accurately dispenses the filling amount, ensuring consistency in each package, whether you use a pouch filling packing machineor other types of packing machines.

- Vertical and horizontal sealing bars: Seal the sides and top of the bags to ensure airtight packaging.

- Cutting device: Separates individual bags or pouches for easy subsequent packaging and transportation.

- Controller interface: Operates and adjusts the automatic packing machine, setting bag length, sealing temperature, filling amounts, and other parameters to meet personalized packaging requirements.

These components work together seamlessly to form an efficient and precise packaging system, enhancing the production flow.

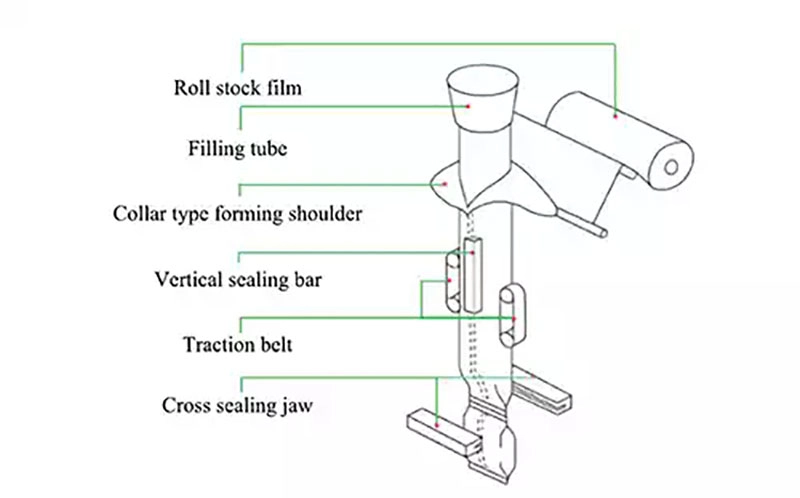

3. The VFFS Packaging Process

Understanding the VFFS packaging process will help you determine whether your products are suitable for this type of packing machine, which is beneficial for selecting the right packaging equipment.

The VFFS automatic packing machine process consists of several sequential steps:

- Film feeding: The film is pulled from a roll into the forming area, initiating the packaging process.

- Bag forming: The film wraps around the forming tube to create a cylindrical structure for the bag.

- Filling the bag: The pouch filling packing machine accurately dispenses the product into the bag, ensuring consistency.

- Sealing: After the bag is filled, the vertical and horizontal sealing bars seal the edges and the top of the bag, maintaining an airtight seal for freshness.

- Cutting: The cutting device separates each bag from the continuous film, creating independent packages ready for further handling.

This method allows VFFS packing machines to facilitate high-speed packaging across various industries, ensuring production efficiency.

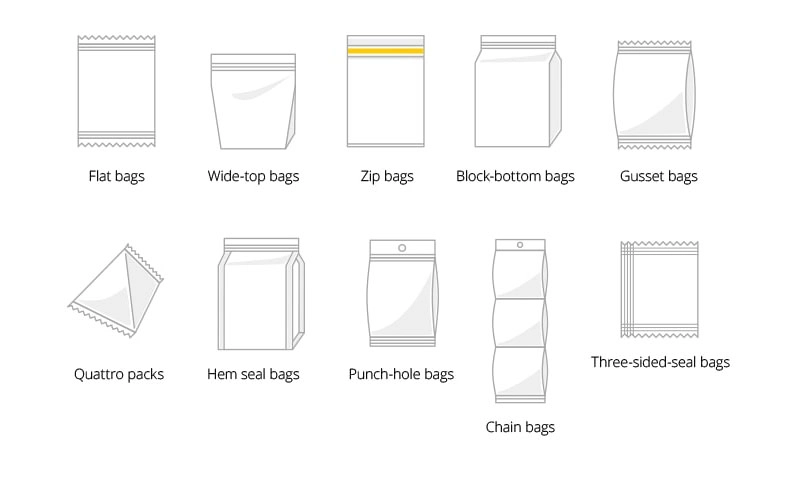

4. Types of Bags Used by VFFS Machines

While VFFS machines may not offer the diverse functionalities of larger industrial vacuum packing machines, they can still produce a variety of bag types to meet specific product and industry needs:

- Pillow bags: Suitable for common food packaging like snacks and dried goods, including those processed with a machine to vacuum pack food.

- Gusset bags: With side fold designs that increase capacity, ideal for coffee beans or larger bulk items.

- Block bottom bags:Flat-bottomed bags perfect for shelf display, enhancing visibility, commonly produced with a pouch packing machine.

- Stand-up bags: Designed to stand on their own, commonly used for liquids or semi-liquid products, often made with a vacuum pack sealer machine.

- Zipper bags: Featuring zipper closures for repeated opening and closing, improving consumer experience, frequently produced using automatic pouch packing machines.

- Four-side sealed bags: Designed for products requiring high sealing standards, such as pharmaceuticals or health supplements, often created using blister packing machine

- Easy-tear bags: With tear openings for easy consumer access, often used for single-serving foods or seasonings, typically made with a stick packing machine.

Choosing the right bag type influences the product’s appearance, convenience of use, and shelf life. After confirming the bag type, you can also contact a packing machine manufacturer for custom bag options or explore our packing machine for sale to achieve the best packaging results. As a reliable manufacturer with over 20 years of production experience, we support custom bag types to meet our clients’ specific packaging needs.

5.Cross-Industry Applications of Compact VFFS Machines

Compact VFFS machines serve various industries, with their efficiency and space-saving design adapting to different production needs. Here are the primary applications across industries:

- Food and Beverage: Suitable for packaging a variety of foods like snacks, cereals, sauces, and instant meals. These machines, such as a food packing machine, can quickly and efficiently package products of varying sizes while ensuring sealing and freshness.

- Pharmaceuticals: Meet the high standards for precise dosing and sterile packaging of powders, tablets, and liquids. The machines, including options like a sachet packing machine or stick pack machine, help avoid cross-contamination, suitable for small-dose pharmaceutical products, and comply with GMP (Good Manufacturing Practice) requirements.

- Chemicals and Fertilizers: Ideal for sealing powdered or granular products like fertilizers, cleaners, and industrial chemicals. VFFS machines, often paired with a vacuum pack machine, prevent moisture or contamination of chemicals, ensuring safe transport and storage.

- Pet Food: Particularly suited for packaging dry food, kibble, and pet treats. The adjustable filling and sealing systems in these machines, like a pouch packing machine, help accurately package different types and quantities of pet food for easy sales and storage.

- Retail and Consumer Goods: Used for the sealed packaging of personal care items, cleaners, and other consumer products, keeping items clean and extending shelf life. Machines such as a vacuum pack sealer machine are commonly used for packaging soaps, cleaning powders, and other daily consumables, ensuring product integrity.

- Cosmetics: Suitable for small sachets of cosmetics, face masks, and sample sizes, with the aid of a sachet packing machine, ensuring compact, attractive packaging for ease of sale and use.

- Hardware and Industrial: Ideal for packaging small parts, screws, nails, and other hardware items, effectively dispensing and sealing them for bulk purchasing and retail. The machine’s versatility, as seen with automatic shrink packing machines, meets various material and size packaging requirements.

This compact design seamlessly integrates into manufacturing environments of different scales, providing reliable and flexible packaging solutions for cross-industry users.

6. Features of Compact VFFS Machines

Compact VFFS machines are equipped with features that cater to small spaces and limited budgets while ensuring efficiency. This setup, which can include options such as a mini sachet pouch packing machine or small sachet packing machine, is designed specifically for SMEs, enough to attract most small and medium-sized enterprises actively.

Their notable features include:

- Small footprint: Designed for facilities with limited space, allowing them to fit in smaller buildings.

- High-speed and precision: Offers rapid filling and sealing, with precise control over the content of each bag, effectively improving production efficiency, a quality often seen in a flow pack machineor bag packing machine.

- Multi-functional film compatibility: Compatible with various materials, including polyethylene, polypropylene, and multi-layer films, making it suitable for both food and industrial products. Machines like thevertical packing machine can handle diverse film materials for flexible packaging.

- User-friendly interface: Simple controls reduce the learning curve, meaning operators don’t need extensive skills, which helps save on labor costs. Packing machine suppliersoften highlight this feature to meet the needs of SMEs.

- Reduced energy consumption: Optimized to minimize energy use, making it more sustainable and cost-effective, similar to innovations seen in case packer machines.

These features make compact VFFS machines an attractive choice for SMEs seeking a balance between performance and space.

7.Factors to Consider When Choosing a Compact VFFS Machine

When selecting the right compact VFFS machine, it is essential to consider not only costs but also several key factors to ensure the machine meets production needs effectively:

- Production speed requirements: Different VFFS machines, such as a case packing machineor flow pack packaging machine, vary in packaging speeds; choose one that meets your expected output. Understand the machine’s maximum speed and stability to ensure it aligns with your production goals.

- Product compatibility: Ensure the machine is suitable for your specific product types, such as solids, liquids, powders, or granules. Different products require distinct filling and sealing methods to ensure packaging accuracy and seal integrity; options like a stick pack machineor sachet packing machine can address various product forms.

- Bag style and size: Confirm that the machine can produce the required bag styles and sizes to meet product display needs. For custom bag types like zipper or stand-up bags, ensure the machine supports flexible adjustments, similar to what a pillow packing machinemight offer.

- Material compatibility: Packaging materials vary widely, including plastic films, composite films, and biodegradable materials. Confirm that the machine is compatible with the chosen materials to prevent jams or poor seals within the packaging equipment, such as those used in a vacuum pack machine.

- Available space: VFFS machines come in various sizes, so ensure your production area can accommodate the selected machine, allowing ample space for operation and maintenance to avoid workflow disruptions. Compact models, like a pouch packing machine, can be ideal for limited space.

Considering these factors comprehensively will help you select the most suitable VFFS machine, enhancing production efficiency and packaging quality.

8. How to Choose a VFFS Machine Manufacturer

Finding a reliable VFFS machine manufacturer is key to ensuring you acquire quality equipment. When selecting a packing machine manufacturer, consider the following:

- Experience and reputation: Look for manufacturers with a strong industry presence and positive reviews. Established manufacturers often offer better warranty conditions and support.

- Customization options: Confirm that the manufacturer can accommodate your unique packaging needs, such as custom bag styles and sizes.

- Customer support and service: Evaluate the manufacturer’s customer service, including installation, training, and ongoing support. A responsive service team is essential for resolving issues quickly and minimizing downtime.

- Quality of equipment: Examine the quality of the machines offered, including components and overall design, to ensure they meet industry standards and reliability.

Considering these factors comprehensively will help you select the most suitable VFFS machine, enhancing production efficiency and packaging quality.

Conclusion

Selecting the appropriate packing machine is vital for SMEs focused on enhancing production efficiency and product quality. Compact VFFS machines provide versatile and effective solutions, accommodating various product types while saving space. By understanding the factors to consider and the benefits of these machines, businesses can make informed decisions that improve their overall operations. Partnering with a reliable packing machine supplier will ensure that you receive quality equipment and support tailored to your specific packaging needs.